COMET–Center (K1)

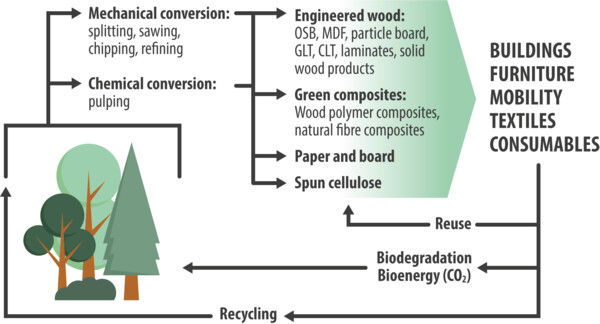

The COMET Center (K1) of the Kompetenzzentrum Holz GmbH (Wood K plus) with the title „WOOD – transition to a sustainable bioeconomy“ is funded within COMET – Competence Centers for Excellent Technologies - by BMK (Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology), BMAW (Federal Ministry for Labour and Economy) as well as the co-financing federal provinces Carinthia, Lower Austria and Upper Austria (see Funding providers). Das COMET programme is managed by FFG (www.ffg.at/comet).

COMET is the red-white-red programme of science and industry to support application-oriented cutting-edge research in Austria. COMET creates highly qualified jobs and promotes young scientists in Austria. COMET Competence Centers work together with companies and research partners to enable a direct transfer of new knowledge into marketable products, services and processes.

Factsheet Comet-Center - Kompetenzzentrum Holz GmbH (Wood K plus)

Success Stories Wood K plus (selection):

-

Production of bio-based resols from structure defined lignin oligomers (Lignowert)

-

Eco-efficiency - linking environmental and economic impacts of the bioeconomy

-

Improvement of acetic acid and furfural production in a wood biorefinery

-

Wood-polymer-composites: portfolio with completely new properties

-

Sample preparation for atomic force microscopy and infrared microscopy

-

Statistical design of experiments for knowledge-based production

- Microbial upgrading of a side stream from cellulose fiber production

- Melamine-based self-healing coating systems

- More efficient membrane separation through better understanding of molecular interactions

- Mathematical model provides insight into gluing of wood particles

- New ways to produce superhydrophobic wood surfaces

- Weather-resistant coating systems for wood and wood based composites

- Bio-based materials for additive manufactur-ing (am) with excellent impact strength

- Investigation of the ractivity of furfural for an improved biorefiniery process

- Textile chemical-modified viscose fibers have been successfully developed

- Crosslinked lignosulfonate as biobased material of the future

- Determination of γ-value and xanthate group distribution on viscose by liquid-state 1H NMR spectroscopy

- Bright prospects due to new multi layer coatingsystem

- Understanding new interfaces – a strategic dissertation

- Industry 4.0.: Potential for the digisation of the Austrian sawmill industry

COMET – Module

i³Sense - intelligent, integrated and impregnated cellulose based sensors

Main location: Linz (Upper Austria)

Other locations: St. Veit an der Glan (Carinthia), Tulln (Lower Austria)

Thematic area: Material & Production (according to www.ffg.at/comet/netzwerk)

Thematic focuses

Natural fiber reinforced composites (NFC) and load-bearing wood composites are a sustainable basis for a new generation of high-performance and environmentally compatible structural materials. Potential applications are broad, ranging from automotive and construction to renewable energy generation. Unsolved challenges for application in these areas are the extreme hygrothermal and mechanical loads and the resulting damage, in many cases with catastrophic effects (breakage of wind blades, collapse of statically important building parts, etc.). Early detection of moisture-related overstress, the impact of small imbalances in manufacturing and the like is therefore a critical success factor.

The goal of i³Sense is to unlock the full potential of sustainable composites in a wide range of applications and provide safe alternatives to conventional systems with high carbon footprints using smart, integrated, and impregnated cellulose-based sensors.

Graphical representation of the i3Sense module project

Planned realisation and outcomes

To solve this challenge, we will take a radically new approach in which the sustainable materials themselves (wood, the reinforcing fibers, and/or the matrix) become an imperceptible embedded sensing system. In our approach we are capable of measuring changes in moisture, mechanical stress, and temperature in situ without compromising the structural integrity of the high-tech composites, which will allow us to close the gap between sustainability and performance.

The research objectives are

- to understand how hygrothermal and mechanical stresses alter the electrical properties of the polymeric matrix or adhesive, the composite, and the materials used,

- to explore how these properties can be exploited (modified) and read out,

- to use this knowledge to detect the changes in state in real time,

- to study how the modification interacts with the matrix and changes the properties,

- monitor structural integrity over long periods of time.

Industrypartners:

- Audi AG

- Delfort Papierfabrik Wattens GmbH & Co. KG

- FACC Operations GmbH

- FunderMax GmbH

- Hendrickson Commercial Vehicles Europe GmbH

- Kästle GmbH

- Metadynea Austria GmbH

- RAC GmbH

- Stora Enso Wood Products GmbH

Scientific Partners:

- ETH Zürich

- Johannes Kepler Universität Linz

- Mendel Universität Brno

- Universität für Bodenkultur

- Universität Bremen

Duration: 01.01.2022 to 31.12.2025 (4 years)

Management: DI Boris Hultsch (Geschäftsführung; CEO)

Prof. Dr. Wolfgang Gindl-Altmutter (wissenschaftliche Leitung)

Project Management:

Priv.-Doz. DI Arunjunai Raj Mahendran, PhD

Priv.-Doz. DI Arunjunai Raj Mahendran, PhD  DI Franziska Hesser, PhD

DI Franziska Hesser, PhD

DI Claudia Pretschuh Claudia, PhD

DI Claudia Pretschuh Claudia, PhD  DI Martin Riegler, PhD

DI Martin Riegler, PhD

Success Stories Wood K plus (Module):

Press und Media Contact:

For media inquiries please contact zentrale@wood-kplus.at or Tel.: +43 732 2468-6750.