Bioraffinerieprozesse und

Bio-Composite Werkstoffe

Forschungsinhalte

Der Forschungsschwerpunkt im Bereich Bioraffinerieprozesse und Bio-Composite Werkstoffe liegt bei der Optimierung der Nutzung von Biomasse – vor allem Holz – aber auch anderen nachwachsenden Rohstoffen. Mit mehr als 20 Jahren Erfahrung und über 40 hoch qualifizierten Wissenschafter*innen, organisiert in vier Forschungsteams, sind wir ein idealer Forschungspartner für industrielle und strategische Fragestellungen in den Bereichen der Holz- und Holzkomponentenchemie, der Zellstoffqualität und der chemischen bzw. biotechnologischen Verwertung von lignocellulosischen Rohstoffen.

Angefangen von der Vorbehandlung von Biomasse über den Aufschluss in Druckreaktoren, die Separation der wertstoffhaltigen Ströme und natürlich die Methodenentwicklung in der dafür notwendigen instrumentellen Analytik sind Teil unserer Expertise. Ein weiterer Schwerpunkt unserer Forschungsaktivitäten liegt im Bereich Composite aus nachwachsenden Rohstoffen (NFC-Natural Fiber Composite) sowie biobasierte Carbon-Materialien. Mittels Extrusion, Spritzguss, Pressen, Schmelzspinnen oder 3D-FLM-Druck sind diese Materialien zu innovativen Produkten mit gezielt einstellbaren Eigenschaftsprofilen verarbeitbar. Unser einzigartiges Know-How ermöglicht es zudem Hybridmaterialien, Carbid-Keramiken und poröse Kohlenstoffe aus biogenen Rohstoffen herzustellen und zu komplexen Teilen zu verarbeiten. Zudem wird an der Entwicklung von biobasierten Carbonfasern und im Bereich biobasierter Elektrochemie geforscht.

Unsere Forschungsthemen umfassen:

- Erarbeitung des grundlegenden Verständnisses der chemischen Reaktionen in Aufschlussverfahren und der Umsetzung dieser Erkenntnisse in neue oder verbesserte Verfahren

- Vorbehandlung von Biomasse und zellulosehaltigen Nebenströmen zur Optimierung des Aufschlusses

- Materialeffiziente zellulosebasierte Spezialprodukte

- Intelligente Verfahren zur selektiven Gewinnung der jeweiligen Bestandteile der Biomasse und deren weitere Nutzung – stofflich und/oder energetisch

- Verfahrensentwicklung im Umfeld von Textilrecycling

- Forschung im Bereich CO2 basierter Chemikalien

- Chemische, insbesonders heterogen-katalytische und/oder biotechnologische Konversion von Abbauprodukten der Lignocellulosen zu Plattformchemikalien

- Folgechemie von Zellulose, Hemizellulose und Lignin- Derivatisierung und Funktionalisierung

- Entwicklung analytischer Methoden – vom Labor bis zur Anwendung im industriellen Prozess

- Optimierung thermoplastischer Verarbeitungsprozesse

- Compounding

- Profilextrusion (auch Schäumen und Coextrusion)

- Spritzguss (auch Schäumen)

- Schmelzspinnen

- Herstellung von Filamenten (auch kurz- und endlos-faserverstärkt) für 3D-FLM Druck

- Entwicklung und Optimierung von Thermoplastrezepturen (Schwerpunkt Biopolymere)

- Entwicklung von biobasierten Carbid-Keramiken

- Entwicklung von Carbonfasern und Carbonfaser-Vorstufen aus biobasierten Rohstoffen

- Forschung und Entwicklung im Bereich biobasierter Komponenten für elektrochemische Anwendungen (Batterien, Brennstoffzellen, Super-Kondensatoren

Team Pulp & Fiber Biorefinery

Das Team Pulp & Fiber Biorefinery beschäftigt sich im Wesentlichen mit Fragestellungen zum chemischen Holzaufschluss, neuen Rohstoffen für die Zellstoffherstellung, sowie neuen Produkten aus Zellulosefasern. Die Verwertung von Prozessströmen aus der Zellstoff- und Faserindustrie ist ein weiteres Aufgabenfeld in dieser Arbeitsgruppe.

Team Chemische Prozesstechnologie zur Biomasseverwertung

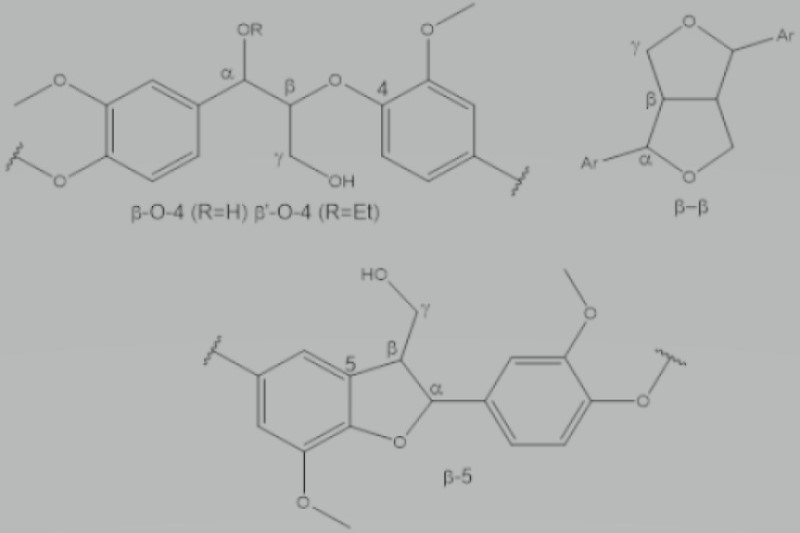

Das Team Chemische Prozesstechnologie zur Biomasseverwertung legt seinen Fokus auf die Modifikation von zellulosischen Materialien, die Generierung von grünen Lösemitteln, die stoffliche Nutzung von Lignin und Ligninderivaten, insbesonders heterogen-katalytische Konversion von Abbauprodukten der Lignocellulosen zu Plattformchemikalien und die Entwicklung von Konzepten für eine kaskadische Bioraffinerie.

Team Biotechnologische Prozesstechnologie zur Biomasseverwertung

Das Team Biotechnologische Prozesstechnologie zur Biomasseverwertung legt seinen Fokus auf die biotechnologische Konvertierung von Prozessnebenströmen zu wertvollen Produkten und die Entwicklung von Konzepten für eine kaskadische Bioraffinerie.

Team Biobasierte Composite, Anwendungen & Prozesse

Das Team Biobasierte Composite, Anwendungen & Prozesse legt seinen Fokus auf die Formulierungs- und Prozessentwicklung innovativer Biopolymere und Composite Materialien. Dies umfasst (Natur-)Faserstärke und (Bio-)Polymere für Kunststoffverarbeitungsprozesse wie Spritzguss, (Co-)Extrusion, Schäumen (Spritzguss und Extrusion), Schmelzespinnen, Filamentherstellung und 3D-FLM Druck (Kurz- und Endlosfaser-verstärkte Polymere). Kernbereiche sind die ökologische Betrachtung, Charakterisierung und Auswahl von Rohstoffen, Verarbeitbarkeit im Compounding und Formgebung. Weiterentwicklung von Simulations- und Modellierungsmethoden für Mischvorgänge und Plastifizierung.

Team Biobasierte Fasern und Carbon-Materialien

Das Team Biobasierte Fasern und Carbon-Materialien legt seinen Fokus auf die Entwicklung biobasierter Carbon-Werkstoffe wie Carbonfasern, Aktivkohle sowie Carbon-Formkörper. Kernbereiche sind die thermische Behandlung der biobasierten Ausgangsstoffe, die Charakterisierung und Modifizierung der Materialien sowie die Ermittlung von Struktur-Eigenschaftsbeziehungen. Die hergestellten Carbon-Materialien werden in Composites, Filtern, Elektroden für Energiespeicher, SiC-Keramiken etc. eingesetzt. Ein weiterer Schwerpunkt umfasst die Forschung im Bereich biobasierter Materialien für elektrochemische Anwendungen.

Ausstattung und Methoden

In unserem Bereich können Entwicklungen und Untersuchungen vom Labor- bis zum Technikums-Maßstab mit eigenem Equipment realisiert werden. Darüber hinaus besteht durch Kooperationen Zugang zum Equipment der Johannes Kepler Universität Linz (JKU).

ANALYTIK & MATERIALPRÜFUNG

- Lignin - und Kohlenhydratcharakterisierung

- Zellstoffanalytik I Nasschemische Methoden

- Porenanalyse I Gasadsorption – Hg-Porosimeter

- Chromatographie I HPLC – SEC – HPAEC-PAD – GC-FID

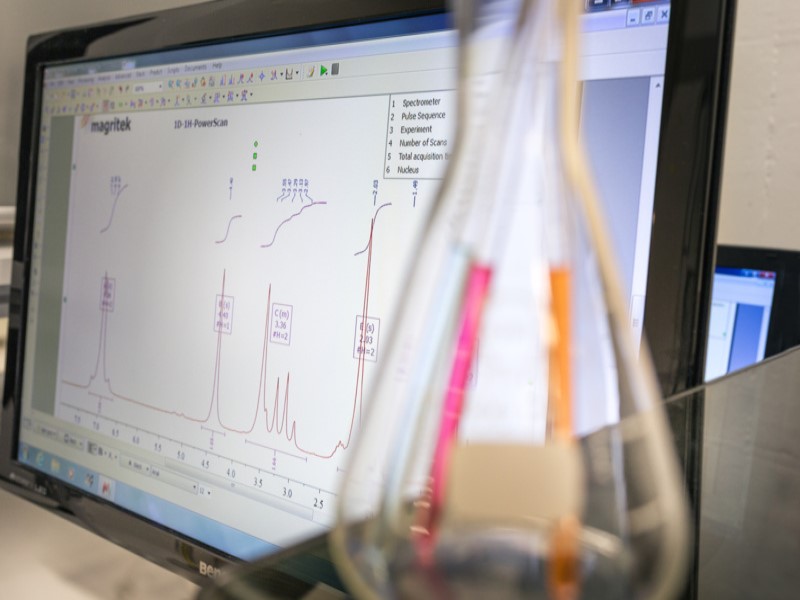

- Spektroskopie I UV-VIS – NMR – React-IR inline – ATR/FTIR heizbar – Datenanalyse

- Thermische Analysen I DSC – OIT, Hochdrucktiegel, Rapid Cooling; HDT-A/B/C

- Optische Analysen I Mikroskopie – REM – XPS

- Mechanische Analysen I Zug-, Biege- und Druckversuche – Schlagzähigkeit – Kugelfalltest – Bauteilprüfung – Einzelfaser-/Fasergarn-/Multifilament-Zugprüfung

- Rheologie I MFR

- Tensiometrie I Kontaktwinkel | Oberflächenenergie | Oberflächenspannung

- Potentiostat I Galvanostat

- Faserstoff-Charakterisierungen I Siebturm – Schüttgewicht – Faserlängen-Verteilung via FASEP

- (Kurzzeit-)Durchschlagfestigkeit I Hochspannungsprüfgerät

- Brandversuche I Einzelflammentest – UL 94 Brandprüfung

- Umweltsimulation I Schnellbewitterung – Xenon-Bewitterungskammern – Klimatisierung

- Heiz-Kühl-Presse 320 × 320 × 200 mm

BIOMASSEAUFSCHLUSS

- Probenvorbereitung I Kugel- und Schneidmühle – Gefriertrockner – Extraktion

- Druckreaktoren I Stahl- und Glasreaktorstationen 300 ml, 1000 ml, 3000 ml

- Aufreinigung und Separation I Membranfiltrationsanlage Labormaßstab – Chromatographie Säule im Labor- und Pilotmaßstab – Ultrazentrifuge 8 × 50 ml bis 6 x 1000 ml

- Funktionalisierung von Biopolymeren

BIOTECHNOLOGISCHES LABOR

- Biotechnologische Konvertierung von Prozessströmen

- 4-fach Parallelfermenterstation 2000 ml

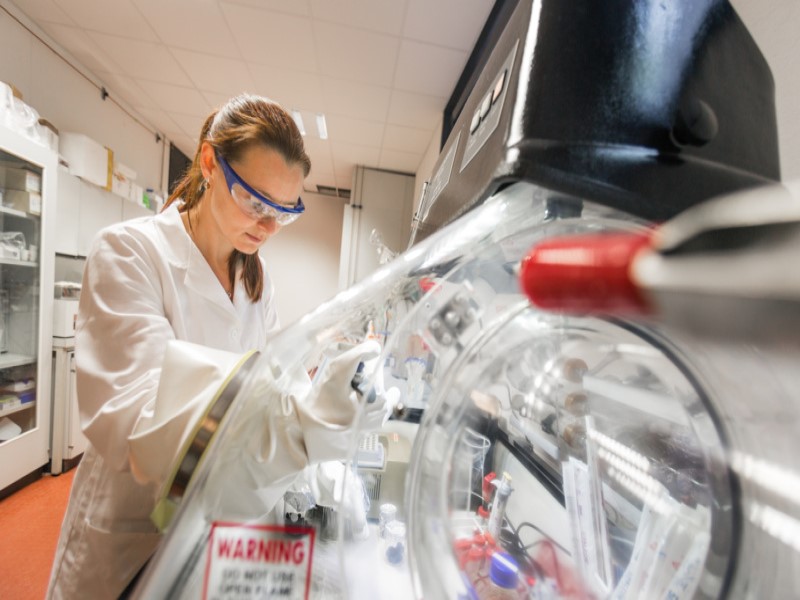

- Anaerobzelt

- Biotechnologisches Standard-Equipment

EXTRUSION/COMPOUNDING

- Faserstoff-Extrusionslinie I Gegenläufiger, konischer Doppelschneckenextruder – Ausstoß max. 50 kg/h I Kalibriertisch – Abzug – Säge

- Diverse Extrusions-Werkzeuge I inklusive Schlitzkapillar-Rheologie

- Einschneckenextruder – Co-Extruder I Ausstoß max. 30 kg/h

- Gleichläufiger, paralleler Doppelschneckenextruder I Ausstoß max. 15 kg/h

- Gegenläufiger, konischer Doppelschneckenextruder I Ausstoß max. 5 kg/h

- Granuliersysteme I Heißabschlag-Granulierung – Unterwasser-Granulierung – Strang-Granulierung

- Filament-Extrusionslinie I Kurz- und Endlosfaserverstärkte 3D-Druck-Filamente

- Multifilament-Schmelzspinnanlage I Ausstoß max. 3,0 kg/h

- Messkneter I 55 ml – 370 ml

SPRITZGUSS

- Hydraulische Spritzgussmaschine I Schließkraft 120 t – Dosiervolumen 160 cm³ – Spritzeinheit für Thermoplaste und Duromere

- Chemisches Schäumen durch exakte Werkzeugöffnung

- Diverse Werkzeuge I Prüfkörper-Geometrien – Fließspirale – Platten

- Granulattrockner I 4 × 30 – 1 × 50 l

- Zahnwalzenmühle für Recyclingversuche

3D-DRUCK

- FLM-Drucker I Druckraum: 390 × 400 × 330 mm

- FLM-Drucker I Multi Material Kit I Druckraum: 250 × 210 × 210 mm

- 3D-Scanner I Messfelder: 45-500 mm – Auflösung: 5 Megapixel – max. Genauigkeit: 18 µm

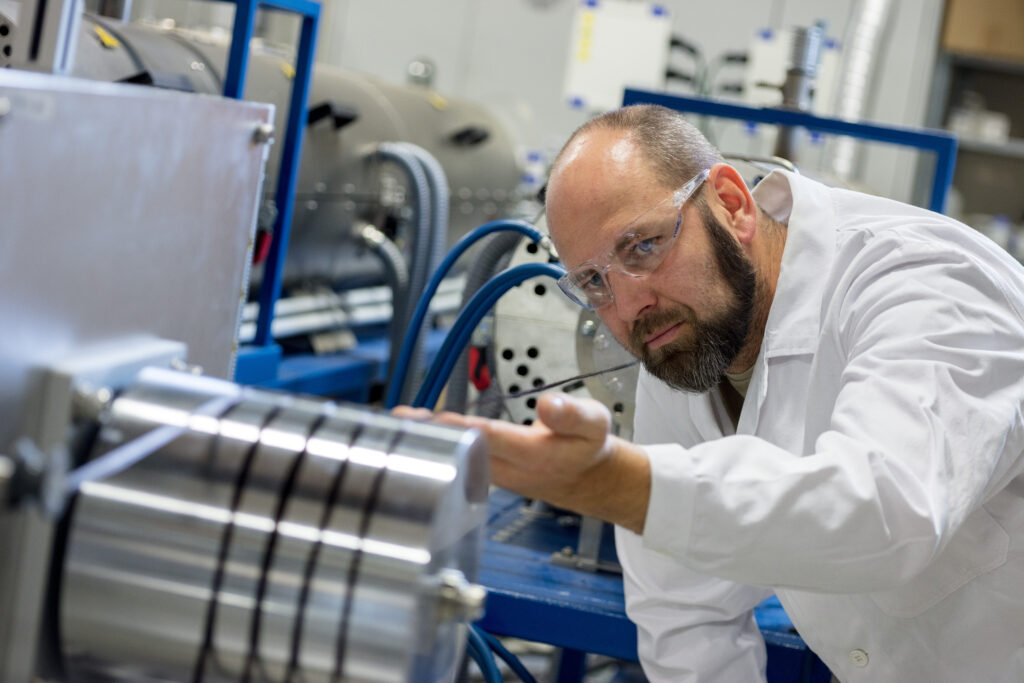

HOCHTEMPERATURANLAGEN

- Hochtemperatur-Kammerofen I bis 2.300 °C – Retorte 6 l Nutzvolumen

- Kammerofen I bis 900 °C – 150 l Nutzvolumen

- Drehrohrofen I bis 1.100 °C

- Rohrofen für Oxidation/Stabilisierung I bis 300 °C – 5 Heizzonen zu je 50 cm

- Rohrofen für LT-Carbonisierung I bis 1.050°C – 5 Heizzonen zu je 50 cm

- Rohrofen für HT-Carbonisierung I bis 1.700°C – 2 Heizzonen zu je 50 cm

Ansprechpartner

im Bereich Bioraffinerieprozesse und Bio-Composite Werkstoffe

DI Dr. Robert Putz

Bereichsleitung

Teamleitung Chemische Prozesstechnologie zur Biomasseverwertung

DI Dr. Manfred Schöflinger

Bereichsleitung

Teamleitung Biobasierte Composite, Anwendungen & Prozesse

DI Dr. Christoph Unterweger

Teamleitung Biobasierte Fasern und Carbon-Materialien

DI Dr. Michael Egermeier

Teamleitung Biotechnologische Prozesstechnologie zur Biomasseverwertung

Profin Dr.in Rer. Nat. Habil

Birgit Kamm

Key Researcher

Kontakt und Anfahrtsplan

Adresse

Kompetenzzentrum Holz GmbH

Bereich Bioraffinerieprozesse und Bio-Composite Werkstoffe

Science Park, Bauteil 2, 2. Stock – Trakt A

Altenberger Straße 69

4040 Linz, Austria

Mit dem Auto von der Westautobahn (A1) kommend

Abfahrt beim Knoten Linz auf die Mühlkreisautobahn (A7) in Richtung Linz bis Abfahrt Linz-Dornach, danach immer geradeaus bis zur Johannes Kepler Universität Linz. Der Science Park befindet sich auf der rechten Seite. Parkmöglichkeit besteht am Freiparkplatz davor sowie in der Tiefgarage.

Anreise mit dem Zug

Ab Hauptbahnhof Linz mit Straßenbahnlinie 1 oder 2 in Richtung Universität bis zur Endhaltestelle „Universität“ fahren. Danach Fußweg zum Science Park ca. 5 Minuten.