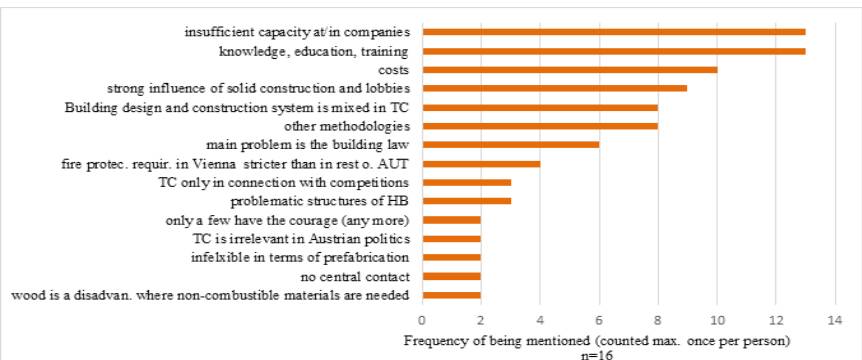

Barriers for multi-storey timber construction in urban areas

Survey of actors in non-profit housing projects shows the need of specialist knowlede and public visibility.

Survey of actors in non-profit housing projects shows the need of specialist knowlede and public visibility.

„Wood be better!“ ist ein Forschungsprojekt aus der Förderschiene Talente regional der FFG. Im Projekt werden Kinder und Jugendliche aus insgesamt sechs Schulklassen bzw. Kindergartengruppen im Raum Tulln über einen Zeitraum von zwei Jahren gemeinsam mit Wissenschafter/Wissenschafterinnen und Techniker/Technikerinnen verschiedene Fragestellungen aus dem Bereich der Holzforschung und Holztechnologie spielerisch und altersgemäß aufbereitet kennenlernen, und das spannende, heimische, biologische und nachhaltige Material Holz mit all seine Facetten und Möglichkeiten verstehen und anwenden lernen.

Environmentally friendly spraying process prevents unwanted water uptake of wood products by means of the “lotus effect”.

Successful international research cooperation leads to improvements of wood plastic composites and powder coatings enabling the durability for exterior use of wood composites.

Since September 2019, Wood K plus has been working on a strategic dissertation at its site in Tulln, which deals with a well-known but nevertheless red-hot topic. The focus is on research into the thermal decomposition of wood and other renewable resources. Old knowledge about pyrolysis, gasification, ignition and combustion is to be used and supplemented by new investigations and measuring methods. In addition to a better understanding of thermal degradation, the knowledge gained will contribute to a more targeted and efficient use of wood and renewable resources.

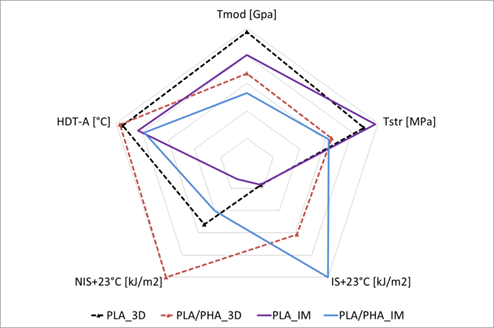

Due to increasing use of bio-based materials, blends of pla and pha are investigated in the field of 3d-flm printing.

Seit Mitte März sind verschiedene Verordnungen und Maßnahmen seitens der österreichischen Bundesregierung gesetzt worden, um die Ausbreitung des Coronavirus möglichst gut einzudämmen. Jene werden nun aufgrund der erzielten Erfolge schrittweise gelockert.

Methods for equiping viscose fibers with optical brighteners and special wet chemical functionalizations, like hydrophobizing, developed in the laboratory and upgescalted in the industry. the physilal chemical properties of the products have been determined.

Wood K plus employees won the Georg Haberhauer Administration Award 2019 in collaboration with the Institute for Chemistry of Renewable Resources (BOKU).

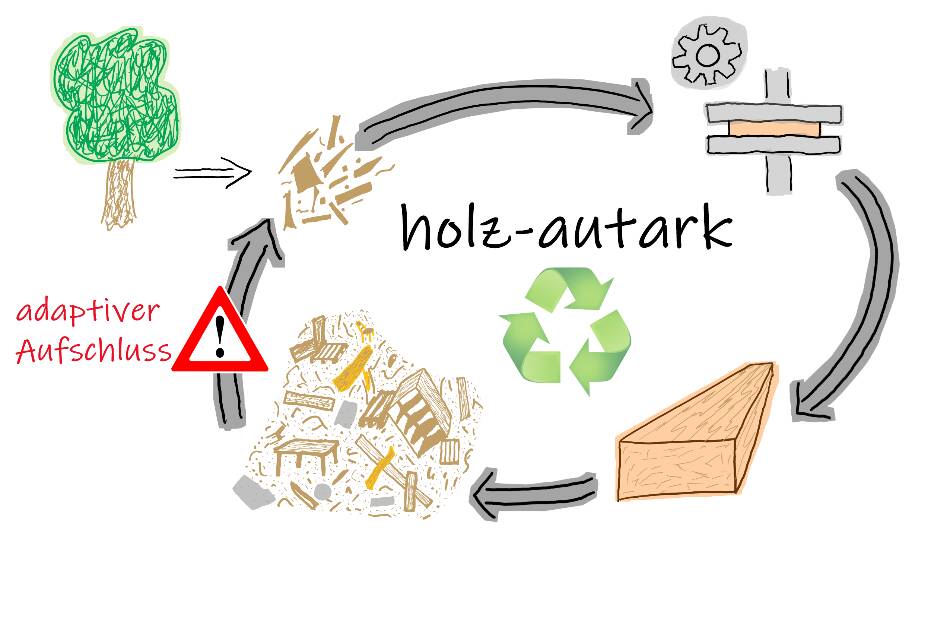

Im Projekt ‚holz-autark‘ werden Grundlagen beforscht die es ermöglichen, Altholz mechanisch aufzuschließen, ohne dessen Eigenschaften wesentlich zu verschlechtern. Auswirkungen verschiedener mechanischer Zerteilungstechniken (Verfahrens- und Werkzeugparameter) auf die Partikelqualität werden untersucht, um den idealen Altholzspan zu identifizieren.

The IQEC team (indoor quality and emission control) of the area Tulln was recently able to record a great success: Within the framework of the FFG Collective Research program line the 3-year industrial project PineXLAM has been successfully completed. PineXLAM, short for CLT (cross laminated timber) made of pine wood, dealed with the characterization and optimization of the production processes for pine wood based cross laminated timber with regard to the reduction of VOC emissions, to enable its use for interior purposes. The consortium comprised he five largest Austrian cross laminated timber manufacturers (Stora Enso, KLH, Mayr-Melnhof, Binderholz and Hasslacher Group) as well as the professional association of wood industry.

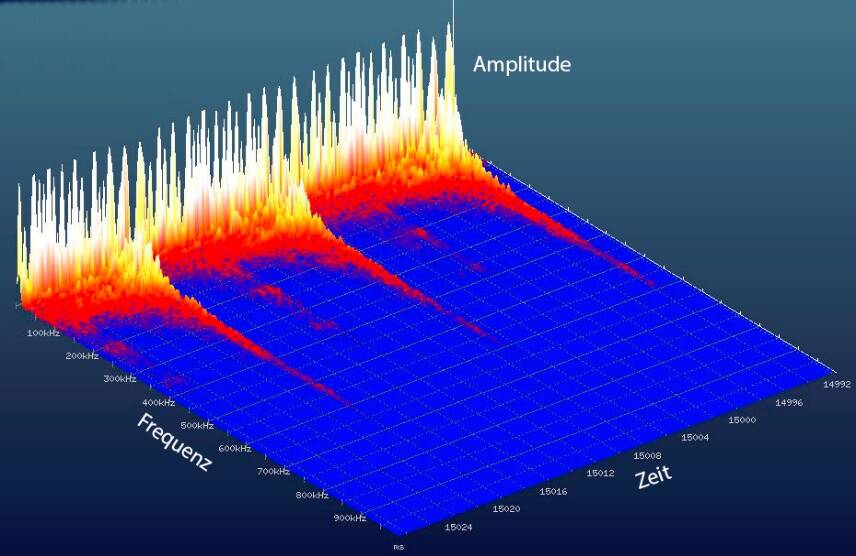

Das Projekt ‚WoodSonics‘ schafft die wissenschaftlichen Grundlagen für adaptive Fertigungstechniken in der Holzindustrie. Die Prozessüberwachung durch Analyse der bei der Verarbeitung auftretenden Schallspektren ermöglicht zukünftig eine deutliche Effizienzsteigerung sowie eine Verringerung von Rüstzeiten und Anlagenausfällen.

Additive manufacturing or 3D printing is superior to other processes in terms of cost efficiency, customizability and sustainability and is therefore gaining ground in more and more areas. The possibilities are not yet optimized in all extents. The FFG project eFAM4Ind - endless fiber reinforced additive manufacturing for industrial applications, which was launched in April 2020, aims to explore these in the high-performance product segment and lightweight construction: Under the direction of the Chair of Materials Science and Testing at the University of Leoben and together with SinusPro, the Polymer Competence Center Leoben (PCCL), the Competence Center Wood and Head Sport as research partners, testing and simulation routines for predicting the durability and service life of fiber-reinforced components from the 3D printer are to be developed.

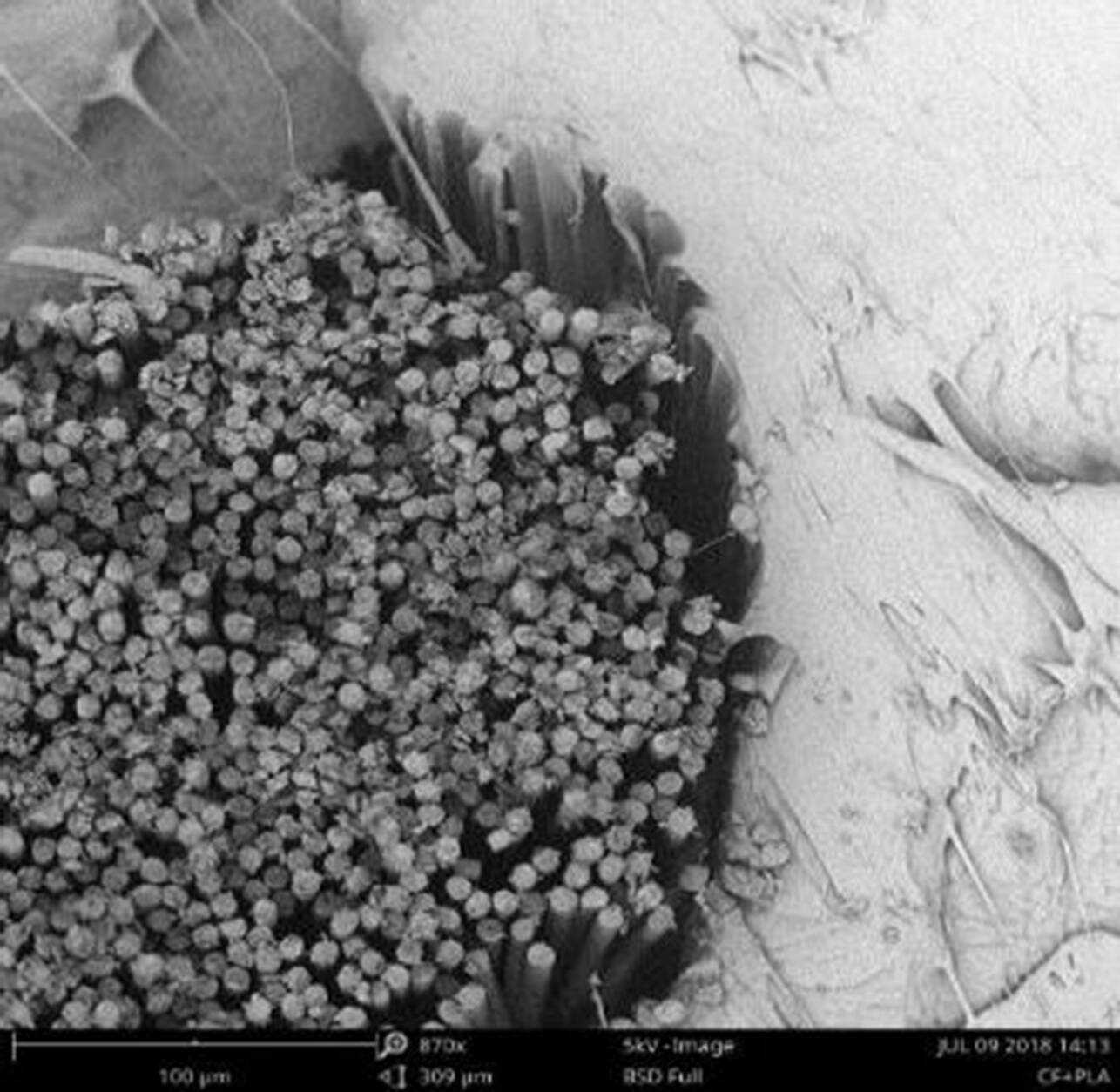

Within the 3-year M-ERA.NET project “3D-CFRP” Wood K plus works together with international industrial partners and universities on the development of new material combinations as well as the optimization and adaptation, respectively, of processing methods for the production of additively manufactured structural components made of endless-fibre-reinforced thermoplastics.

Furfural is gained as side-product from the pulping process and causes insouluble depositions in the plant. wood k plus investigated influencing factors in order to be able to aviod them in the future.

Corona virus information

Wood K plus wird im Zuge eines neuen FFG (Bridge) Projektes in Kooperation mit Lenzing AG an der Verwendung von UV-Licht zur Entgiftung von Prozessablaugen aus der Zellstoffindustrie forschen. Anschließend werden aus diesem Ablaugen organische Säuren mikrobiell gewonnen.