News

Am 20. Oktober 2025 fand in Linz der erste SDG-Workshop statt. Gemeinsam mit externen Stakeholdern aus Wissenschaft und Wirtschaft ...

Das europäische Forschungsprojekt „RAW – Computation for a new age of Resource AWare architecture“ entwickelt digitale Methoden, ...

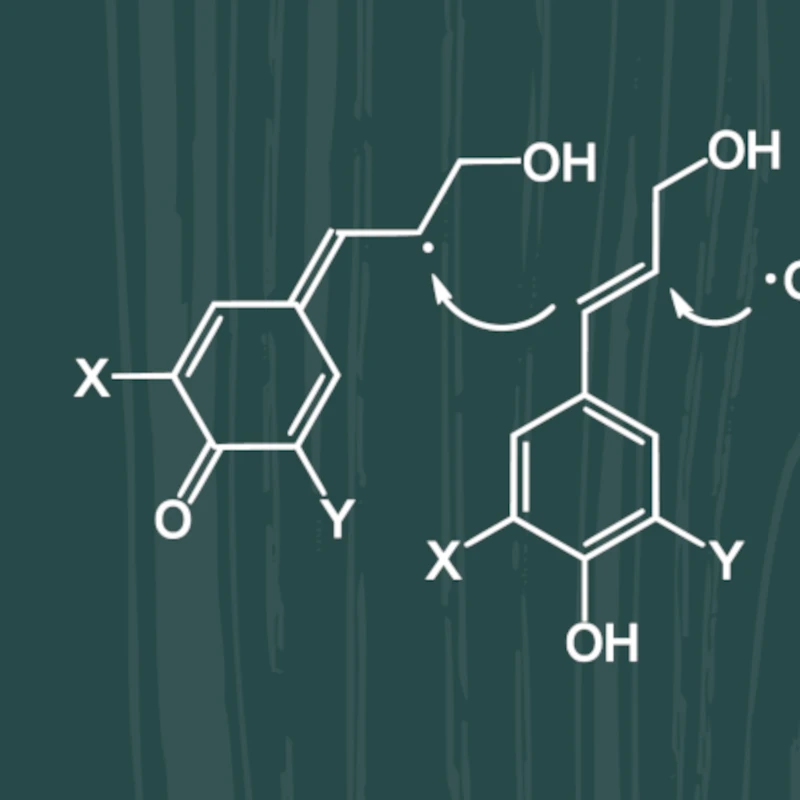

Das FFG-geförderte „Think.Wood“ Projekt „reTHINK.PROTEIN.ADHESIVES“ wurde erfolgreich abgeschlossen und markiert einen wichtigen Fortschritt auf dem Weg zu nachhaltigen, biobasierten Holzklebstoffen. ...

Einladung zur Langen Nacht der Forschung am 24.04.2026 ...

Workshop InterWASTE "Second-life" products made from production waste from the eyewear, furniture, and wood industries ...

Hochdrucklaminate (HPL) sind aus Möbeln, Fußböden und Fassadenverkleidungen kaum wegzudenken. Die robusten Verbundwerkstoffe bestehen aus mehreren Lagen Kraftpapier, die mit Harzen imprägniert werden. ...

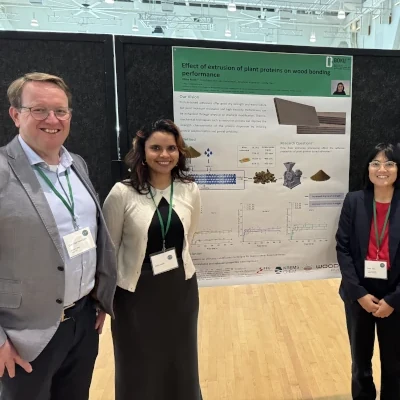

The BOKU DocDay 2025, held at the UFT campus in Tulln/ Donau from September 25th to 26th, brought together doctoral researchers from the University of Natural Resources and Life Sciences ...

Wood K plus from Tulln, in collaboration with FOTEC, Austria’s first ESA_Lab@ (University of Applied Sciences Wiener Neustadt), has launched the GLOW project – Green Low-earth Orbit Woodcraft. ...

Einladung zum praxisorientierten Workshop für KMU ...

𝐕𝐈𝐄𝐋𝐅𝐀𝐋𝐓 𝐆𝐄𝐖𝐈𝐍𝐍𝐓! Gratulation zum 1. Platz an unsere Kollegin Latifeh Nasseri ...

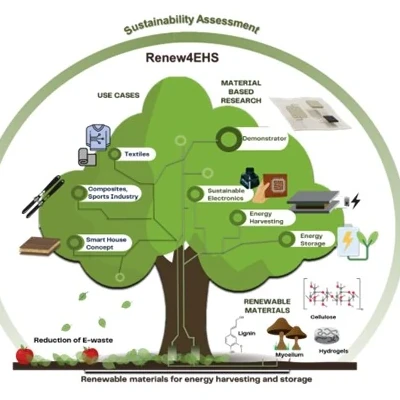

We are pleased to share that our new COMET module has been approved for funding! ...

Kickoff Meeting für die EU Innovation Action SUSBOARD - Erfolgreicher Start eines EU-geförderten Forschungsprojektes ...

The consortium meeting for the Project De-and Remanufacturing for Circular Economy Investments in the Composite Industry - DEREMCO was held from 12th – 14th May, 2025 at Messe, Klagenfurt. ...

Auf der SMART ECCOMAS Konferenz an der JKU wurde dem COMET Modul Projekt „i³ Sense“ und Wood K plus eine eigene Special Session ermöglicht. ...

Innovativer Holzbau mit Weitblick: Mit der Eröffnung des Demonstrators in Tulln und dem Abschluss des Projekts SINK.CARBON ...

Nach den Erfolgen der Projekte „Wood be better!“ und „ReThinkWood“ freut sich das Team von Wood K plus über die Förderzusage für ein weiteres Talente Regional Projekt ...

Einladung zum Symposium "Ökobilanz komplexer Produktionssysteme - Herausforderungen und Lösungen am 04.11.2025 ...

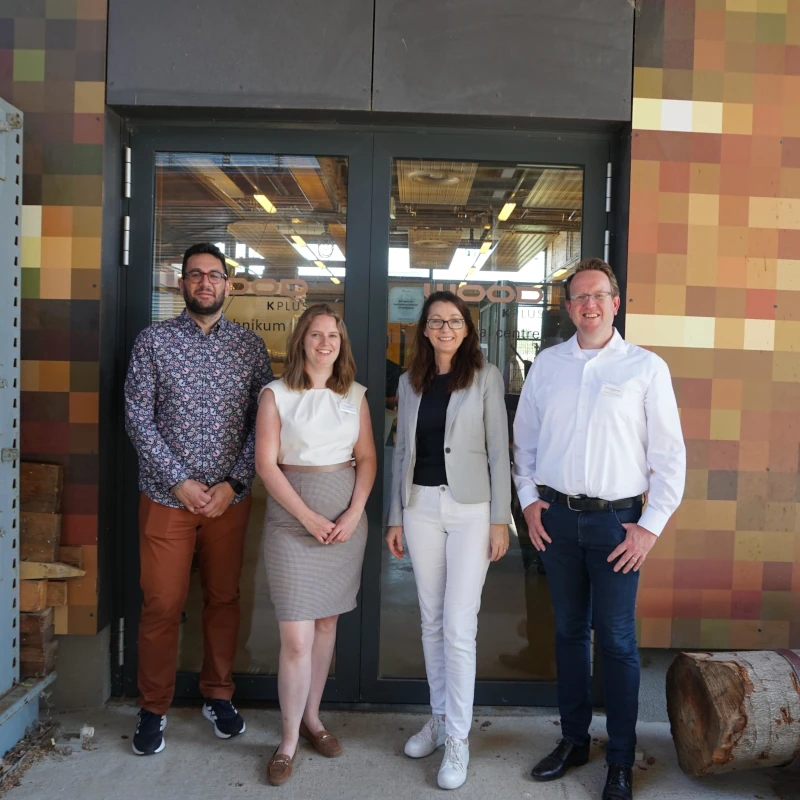

Vom 04. bis 05. Juni 2025 war das Konsortium von „RTIT>>“ zu Gast bei Wood K plus am Standort in Tulln, Österreich am Universitäts- und Forschungszentrum (UFT) der BOKU Universität ...

In der immer internationaler werdenden Forschungswelt ist interkulturelle Kompetenz nicht nur ein „Nice-to-have“, sondern eine entscheidende Zukunftskompetenz. ...

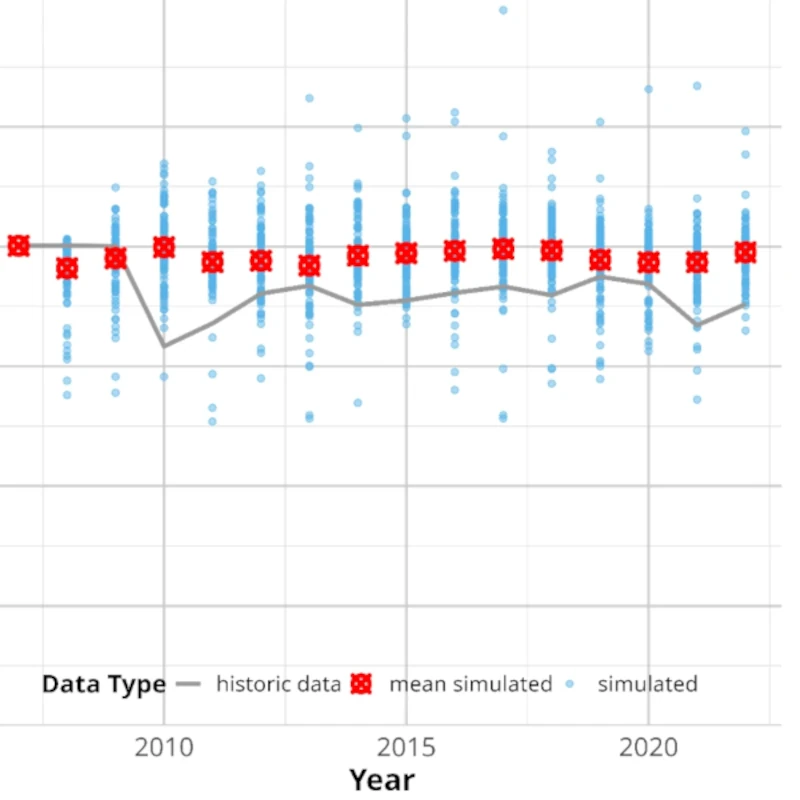

Internationale forstbasierte Lieferketten sind mit inhärenten Risiken und Ungewissheiten konfrontiert, die von verschiedenen Faktoren herrühren ...

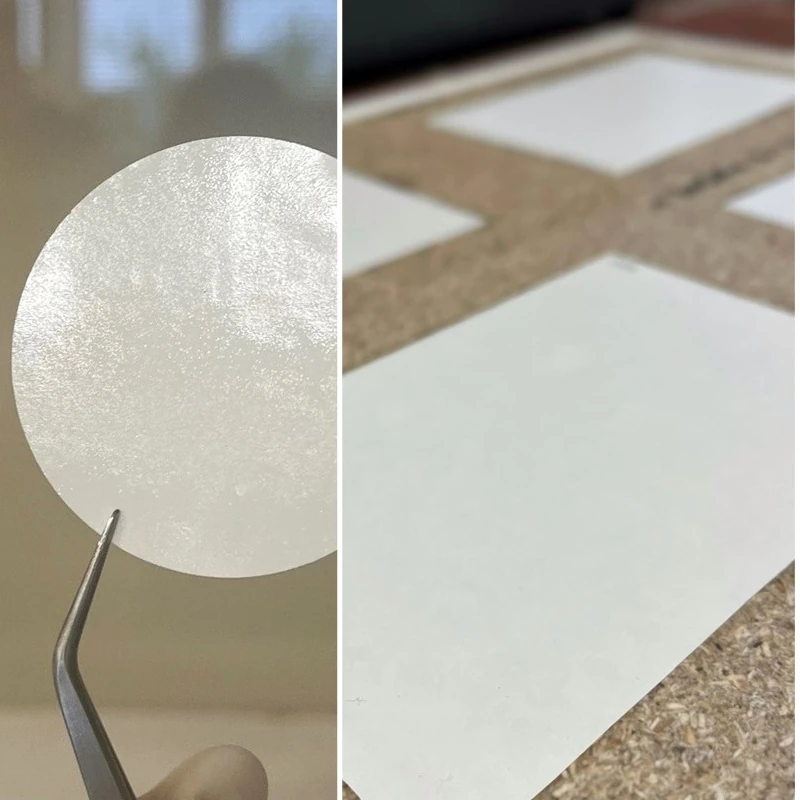

Dekorative Laminate sind aus der modernen Innenarchitektur nicht mehr wegzudenken – sie finden Anwendung in Möbeln, Fußböden und Wandverkleidungen. Mit dem wachsenden Fokus auf nachhaltige Materialien steigt auch der Bedarf ...

Wir freuen uns, dass unser Projekt WOOD4ALL als Best-Practice-Beispiel der HR-Excellence Initiative des UAR Innovation Networks mit einem LT1 Beitrag und einem Preisgeld von 10.000 € ausgezeichnet wurde! ...

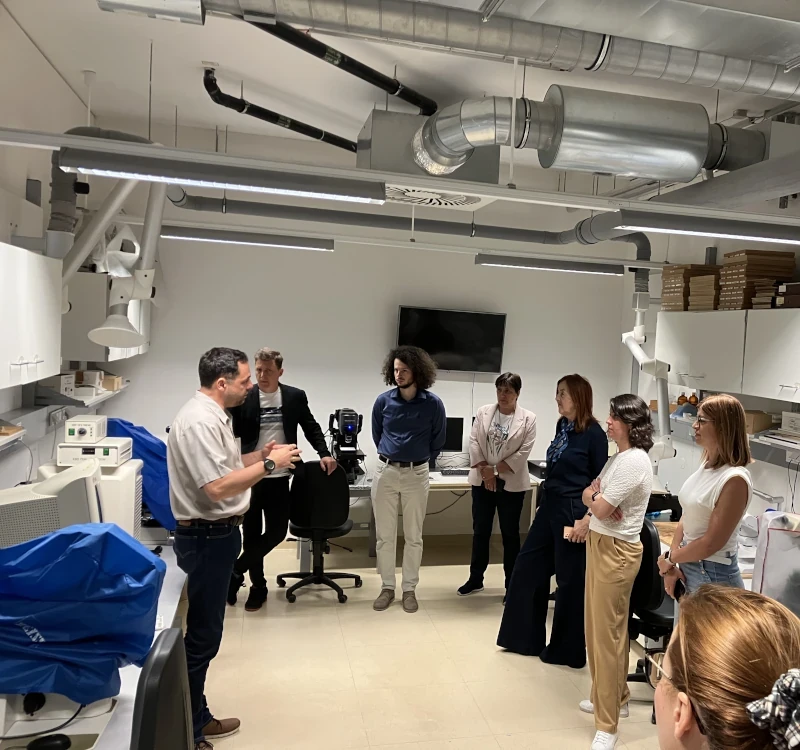

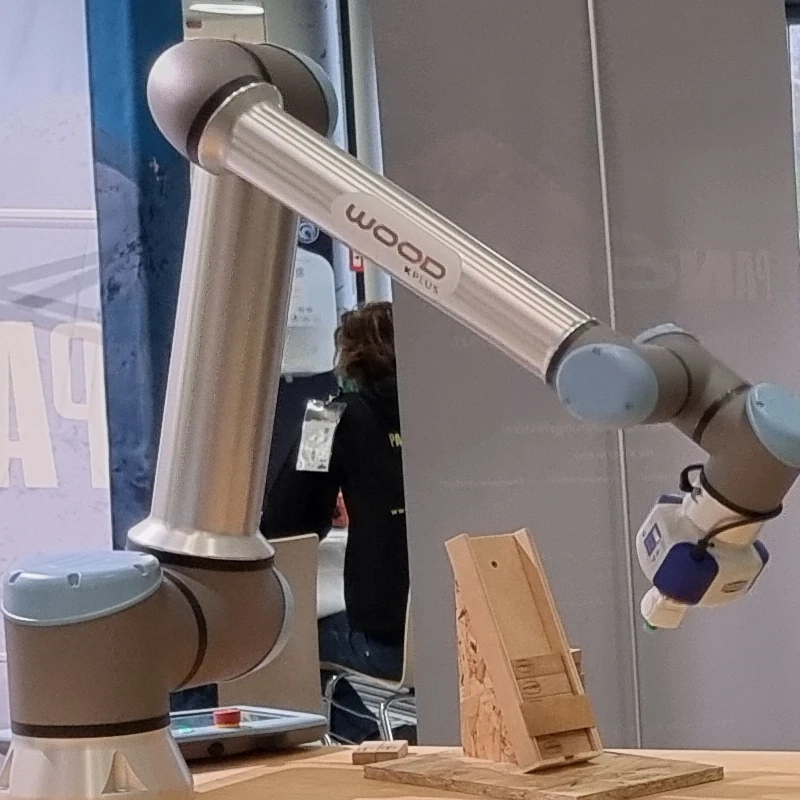

An unserem Standort Massivholz und Holzverbundwerkstoffe in Tulln wurde vor Kurzem eine einzigartige Forschungs-infrastruktur zu digitalen Technologien für die Holzforschung und intelligente Produktion von Biomaterialien und -strukturen eröffnet. Wood K ...

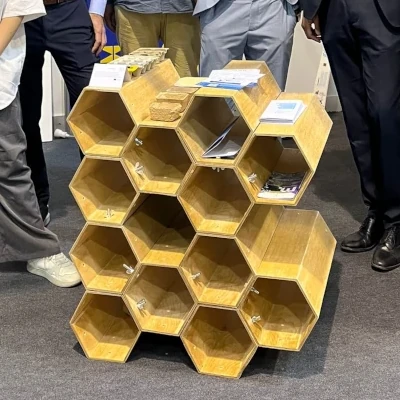

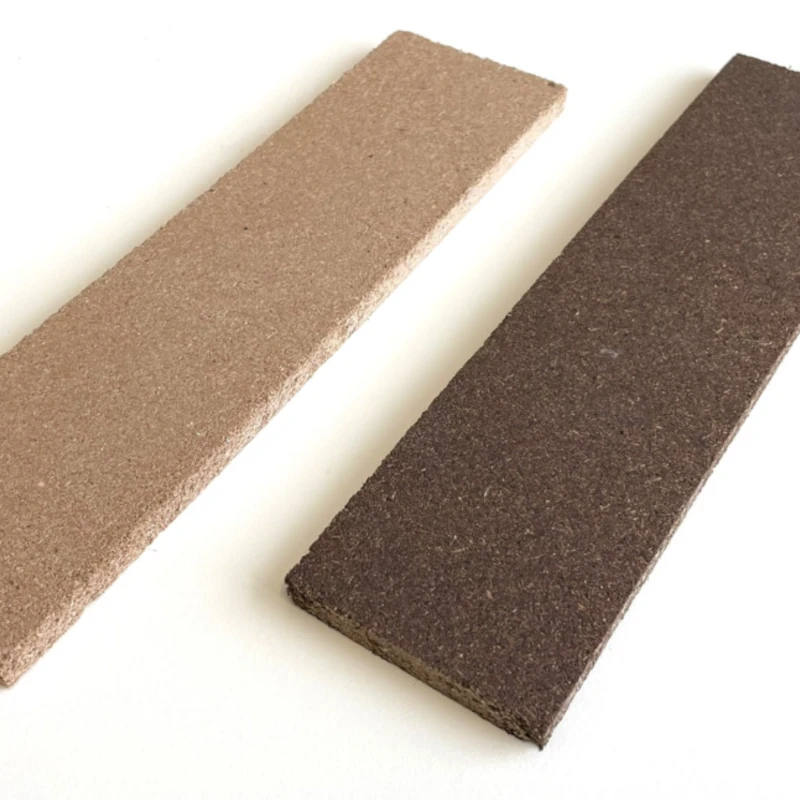

Neuartige 100% biobasierte Holzstaubwerkstoffplatte, herstellbar ohne Wasserzugabe und mittels konventioneller Fertigungsprozesse ...

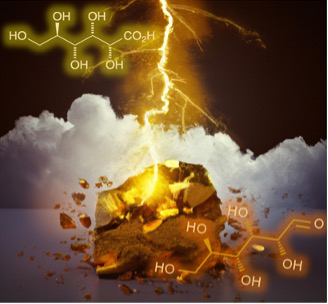

Innovative Verwertung eines Bioraffinerienebenstroms für eine effizientere Nutzung des Rohstoffs Holz ...

Das Projekt: „Flexible Wood“ wurde zum Innovations- und Forschungspreis nominiert. ...

Es ist uns eine Ehre, dass unser Projekt WOOD4ALL im Rahmen der Initiative „HR-Excellence im UAR Innovation Network“ zu den prämierten Best Practice Beispielen gehört! ...

Entdecke die Höhepunkte des Wettbewerbs und lasse dich von unseren Gewinnern und ihren Use Cases inspirieren! ...

Vom 27. – 28.11.2024 durfte Wood K plus die PANORAMA 2024 - das Digitalisierungsfestival für Holz-, Forst-, Land- und Energiewirtschaft in Wels – mit veranstalten. ...

Der Podcast „I am Scientist“ von Daniel Hölle und Philipp Hubert thematisiert den Forschungsalltag junger Wissenschaftler*innen und ihren Weg zur Dissertation. ...

Die letzte Mitarbeiterin unserer WOOD4ALL-Videoreihe „Frauen in der Forschung“ kam über eine Empfehlung ihrer ehemaligen Studienkollegin 2019 zu Wood K plus . ...

Eine weitere Kollegin in unserer WOOD4ALL-Videoreihe "Frauen in der Forschung" begann ihre Reise bei uns als Praktikantin und hat sich mittlerweile als engagierte Projektleiterin etabliert. ...

Die achte Mitarbeiterin in unserer WOOD4ALL-Videoreihe "Frauen in der Forschung" ist nach ihrem Masterstudium an der BOKU seit 2021 bei Wood K plus. ...

Die siebte Mitarbeiterin unserer WOOD4ALL-Videoreihe „Frauen in der Forschung“ kam durch eine Umschulung 2017 zu Wood K plus. ...

In unserer WOOD4ALL-Videoreihe "Frauen in der Forschung" dürfen wir nun eine Mitarbeiterin vorstellen, die in Indien promoviert hat und nun bei Wood K plus als Senior Researcher tätig ist. ...

Das nächste Mitglied unserer WOOD4ALL-Videoserie "Frauen in der Forschung" ist Nachwuchsforscherin bei Wood K plus. ...

Die nächste Mitarbeiterin unserer WOOD4ALL-Videoreihe „Frauen in der Forschung“ kam durch einige FEMtech-Sommerpraktika zu Wood K plus. ...

Die nächste Mitarbeiterin unserer WOOD4ALL-Videoreihe „Frauen in der Forschung“ hatte 2017 die Möglichkeit über ein FEMtech-Praktikum ihre Masterarbeit bei Wood K plus zu machen. ...

Sie ist eine wissenschaftliche Mitarbeiterin bei Wood K plus und Dissertantin am Institut für Umweltbiotechnologie auf der BOKU in Tulln. ...

Die erste Mitarbeiterin unserer #WOOD4ALL-Videoreihe „Frauen in der Forschung“ ist eine junge zweifache Mutter. ...