Solid wood &

Wood composites

Research Interests

The area Wood Materials Technologies is focusing on the development of new bio-based materials, various wood technology processes and the characterisation of wood and wood-based materials and their use in sustainable building and furniture. Their resistance to the negative effects of moisture and humidity, their fire resistance and the significance of emissions from wood-based materials are being closely considered.

Since adhesives play an essential role in the manufacture of advanced wood materials, special attention is dedicated to their synthesis and optimisation towards superior performance and minimised environmental impact. In addition, the interactions between material properties and technological processes and methods are investigated, considering the circular economy and digitalisation.

Research topics include:

- Analysis and optimisation of disintegration processes of wood composites and renewable raw materials

- Drying technology (simulation and optimising industrial drying process)

- Wood and fiber modification

- Surface functionalisation and hydrophobising

- Fire behaviour of renewable raw materials

- Optimisation of production processes to reduce product variability

- Development of new adhesives

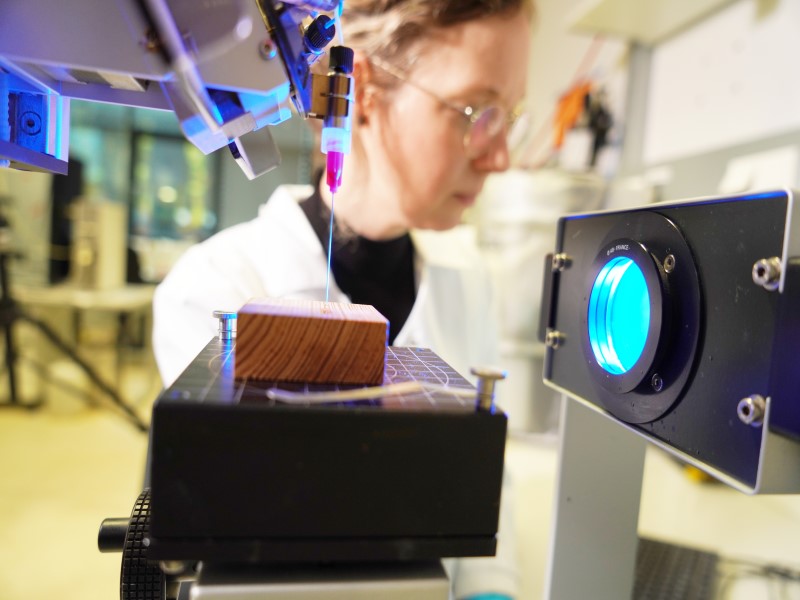

- Analysing adhesive properties (e.g. tack) as well as interactions between adhesive and wood

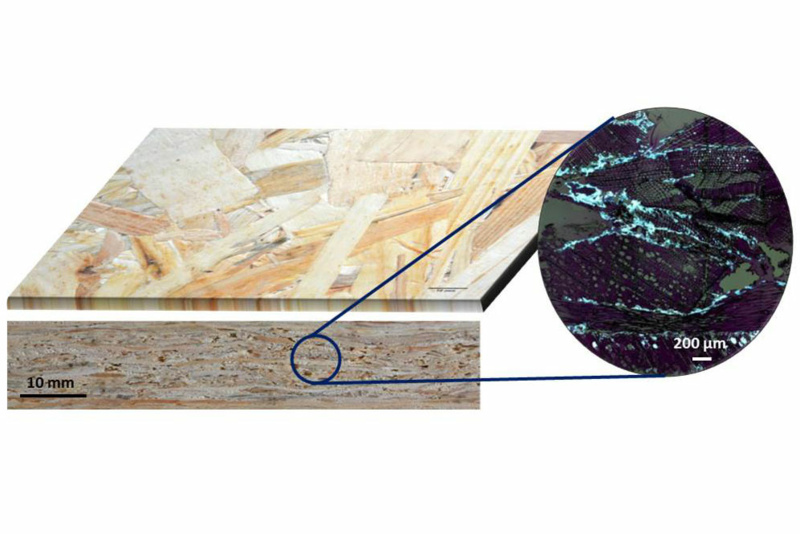

- Adhesive distribution on industrially manufactured wood composites

- Analytic and evaluation of VOC and odours from solid wood and wood composites

- Development of processes for VOC and odour reduction

- Function oriented wood composites by means of „Design Engineering“

Team Circular Wood Process Technologies

The Circular Wood Process Technologies team conducts research into a range of technologies for disaggregation of wood and related materials. In terms of resource efficiency, starting materials from waste streams and underutilised sources are of particular interest. Closed cycles and an adapted understanding of materials and processes lead to the development of sustainable materials.

Team Functional Wood & Bio-based Materials

Within the scope of various projects, the team Functional Wood & Bio-based Materials is working on novel functionalisation methods that lead to improved material properties, particularly regarding fire and moisture resistance. The research topics range from hydrothermal treatments and various functionalisation methods to porous structures and multifunctional wood composites, with a focus on the most bio-based construction applications possible.

Team Advanced Bonding

Bonding is the basis for all wood composites as adhesion and cohesion distribute in their mechanical stability. The team Advanced Bonding investigates adhesive properties and adhesive distribution. Furthermore, new adhesives, also based on renewable raw materials as well as ideal bonding systems for novel wood composites are developed.

Team Digital Technologies & Sustainable Building

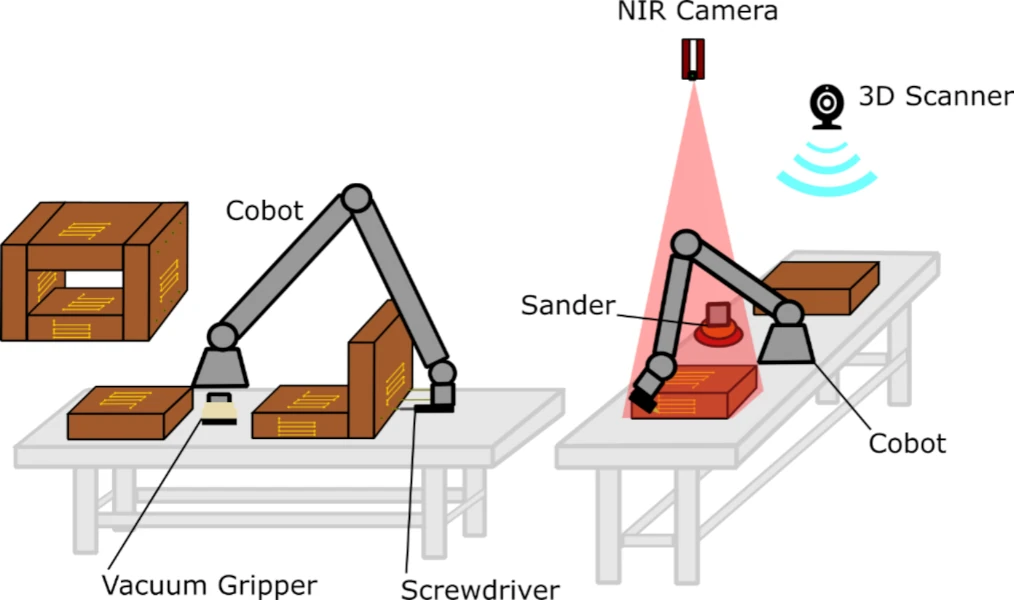

The team Digital Technologies & Sustainable Building deals with current research questions regarding the use of latest digital technologies and methods for woodworking and wood processing as well as with questions about innovative bio-based materials for sustainable building. For example, sensors, assistance systems, robotics, acoustics, machine learning, computer vision or AI are used. With the help of these methods, research questions on innovative sensor technology in timber construction, the traceability of wood along the value chain, process monitoring and modeling or the simulation of wood-hybrid construction elements are pursued, with the aim of extending the use phase of wood and renewable raw materials in the construction industry.

Team Indoor Quality and Emission Control

The team Indoor Quality and Emission Control deals with method development, analysis and evaluation of VOC and formaldehyde from wood composites and wood products, as well as with technologies for reducing undesirable emissions and odors from wood raw materials for wood-based materials and wood products through microbial modification. Another research focus of the team is the utilisation of the growth properties of filamentous fungi, e.g. for the production of mycomaterials.

Equipment and Methods

In the area wood materials technologies, R&D projects from the lab- up to the pilot plant scale can be realised using own equipment. In addition, state-of-the-art infrastructure in wood and natural fiber characterisation and processing is available via cooperation with BOKU Vienna and TU Vienna. Within the technical center besides various test setups also pilot plants can be operated on an area of 450 m².

PILOT AND PILOT PLANTS

ANALYSIS OF CUTTING PROCESSES

- 12’’ lab-refiner I Boiler

- Power measurement I 4-channel

- 3-axis cutting force measurement

- High speed camera

- Fully equipped carpentry and metal workshop

WOOD DRYING AND WOOD MODIFICATION

- Laboratory dryer I convective – fresh air – exhaust air – low temperature – steaming

- High temperature dryer

- Vacuum dryer

- High frequency vacuum dryer

- Autoclave I impregnation – hydrothermal modification

- Chemical modification I functionalisation

MANUFACTURING OF WOOD COMPOSITES

- Particle dryer

- Screening station

- Gluing blender I airless – compressed air

- Laboratory heating presses

- Multivariate statistical process modelling

- Automated image analysis I characterisation of particle morphology

- Test rig I burning behaviour of floorings

- Mini-SBI I downscaled single burning item test

PROTOTYPE CONSTRUCTION

- Carpentry workshop I circular saws – band saw – spindle moulder – planer – thicknesser – long belt sander – CNC

- Metal workshop I lathe – mill 3D print (continuous printer, independent dual extruder printer)

- 3D print (continuous printer, independent dual extruder printer)

TESTING ROOMS / LABORATORIES

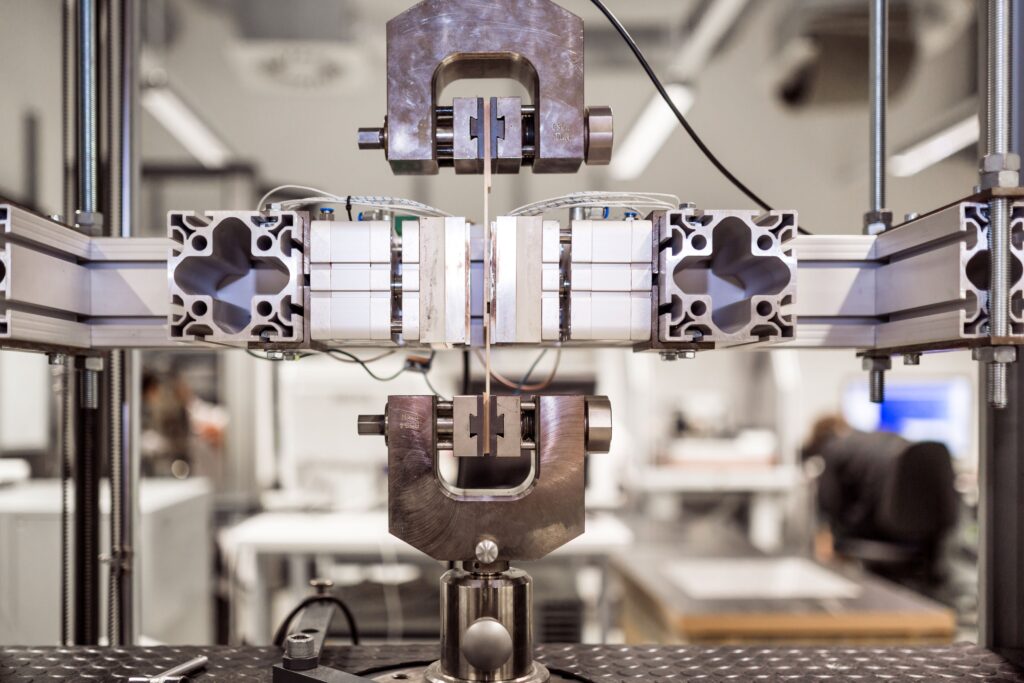

PHYSICAL AND MECHANICAL ANALYSES

- Mechanical analyses I tension – compression – bending – shear – fracture work – axial withdrawal of screws – ABES – pendulum impact test – nanoindenter – DIC – 2D and 3D deformation measurement

- Climate chambers

- Thermal conductivity meters I λ-meter – mini-λ-meter – thermal- and moisture transfer in wall mountings

- Weathering stations I accelerated weathering – outdoor weathering

CHEMICAL LABORATORY

- Adhesive synthesis

- Thermal analyses I DSC – DMA – TG – STA

- Spectroscopic analyses I ATR/FTIR – NIR – UV/VIS – Raman

- Chromatography I HPLC/DAD – RID – FLD – GC/FID – GC/MS SPME – TDA – Headspace

- Rheology I Rheometer – Cold-Tack-Test

- Muffel furnace

- Surface analysis I contact angle measuring system – spectrophotometer– chroma-meter – stylus instrument

- Extraction I pressurised solvent extraction – Soxhlett – autotitration

MICROSCOPIC METHODS

- Microscopic analyses I AFM – UV/VIS –fluorescens microscopy – incident and transmitted light microscopy – digital microscopy – image analysis

- Preparation techniques I rotary and sliding microtome – ultracut – staining techniques

- Electron microscopy I ESEM – SEM – EDX

MICROBIOLOGICAL LABORATORY

- Durability tests I wood preservation against microorganisms

- Isolation and determination of microorganisms

- Cultivation of microorganisms I Rotary shaker – instrumented fermenter –clean bench class I

EMISSION MEASUREMENT

- Emission measurement I micro chambers – 225 L test chambers – 30 m³ model room

- Human sensory analyses I sniffing panel – odour presentation device – GC-O

DIGIWOODLAB

METHODS

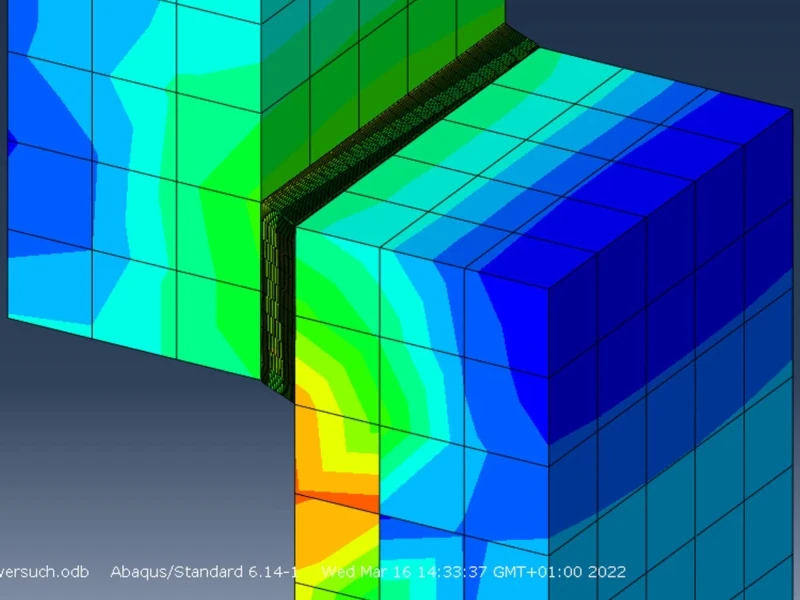

- machine learning | deep learning | computer vision | automated image analysis | pattern recognition | material classification | assistance systems | signal analysis (FFT, etc.) | process modelling (big data, data quality analysis, data fusion, multivariate statistical modelling, quality prediction) | statistical-physical modelling | Finite Element Modelling | design of experiments

HARDWARE

- 3 collaborative robots (Cobots) incl. various end-effectors (gripper, sander, screw driver, dispensing unit, 3D Scanner, cameras) | robot - linear axis | NIR-hyperspectral imaging incl. lab station | laser cutter | two 3D scanner | Spatial Augmented Reality Assistance System | wearables (Augmented Reality glasses, Virtual Reality glasses, smart ear protection) | various cameras (360°, robust, high resolution, etc.) | air-borne sound sensors (robust and optical up to 1 MHz) | structure-borne sound sensors | two powerful workstations | various peripherals e.g. microcontroller, Raspberry Pis, etc.

SOFTWARE

- Abaqus | MATLAB (incl. compiler) | Python | R | SQL | Solid Works | Design Experts | RoboDK | Unity | Vuforia

Contact Person

in the Area Wood Materials Technologies

DI Dr. Christian Hansmann

Area Manager

Key Researcher

DI Dr. Erik van Herwijnen

Deputy Area Manager

Team Leader Advanced Bonding

DI Dr. Stefan Pinkl

Team Leader

Circular Wood Process Technologies

Mag.a Dr.in Cornelia

Rieder-Gradinger

Team Leader

Indoor Quality and Emission Control

DI Dr. Martin Riegler

Team Leader

Digital Technologies & Sustainable Building

DI Dr. Axel Solt-Rindler

Team Leader

Functional Wood & Bio-based Materials

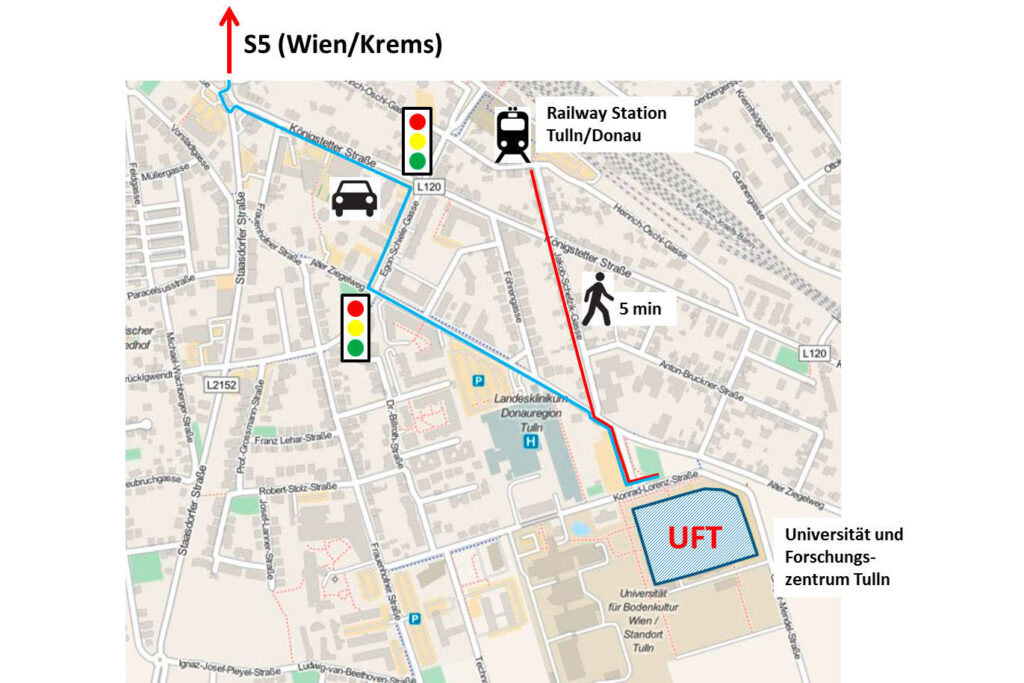

Contact and Directions

Address

Kompetenzzentrum Holz GmbH

Area Wood Materials Technologies

c/o UFT Universitäts- und Forschungszentrum Tulln

Konrad-Lorenz-Straße 24

3430 Tulln/Donau

The area Wood Materials Technologies (except for the working group wood biotechnology, TU Vienna) is located on the Institute of Wood Technology and Renewable Materials, Department of Material Sciences and Process Engineering, BOKU Vienna at campus Tulln.

Office and labs of Wood K plus are located at the University and Research Center (UFT), Konrad-Lorenz-Strasse 24, A-3430 Tulln. Crossing the assembly hall from the main entrance to the staircase on southern part of the building, upstairs on the 1st floor on the right hand you will find the offices of Wood K plus starting at office no. 1.3.119.

By car

From Linz – Salzburg (A1) St. Pölten – S33 direction Krems – Traismaier S33 direction Vienna/Tulln à Exit Tulln.

From Klagenfurt – Graz (A2) A2 direction Vienna à Südosttangente (A23) Exit Kaisermühlen à Donauufer Autobahn (A22) direction Krems à Stockerau S5 direction Krems à Exit Tulln.

Public transport

Train station Vienna Franz Josefs Bahnhof, Vienna Spittelau or Vienna Heiligenstadt à Vienna à Tulln. By foot: crossing Bahnhofstrasse and following Jakob-Schefzik-Gasse ahead to UFT (approx. 900 m).

Train station “Westbahnhof” underground U6 à station „Spittelau” à Vienna à Tulln by train.

Train station “Südbahnhof/Zentralbahnhof” underground U1 à station “Schwedenplatz” à underground U4 à station “Spittelau” à Vienna à Tulln by train.

By Plane

International airport Vienna – Schwechat à City Airport Train (CAT) à underground station „Wien Mitte“ (U3, U4) à underground U4 direction „Heiligenstadt“ à end of the line train station „Heiligenstadt“ à by train Vienna à Tulln (time max. 90 min.).