Biorefinery processes and

Bio-composite materials

Research Interests

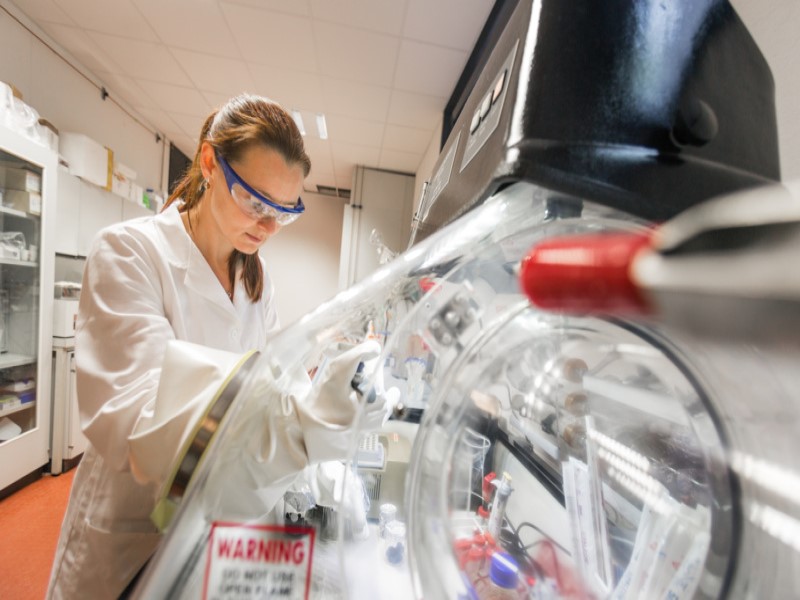

The research focus of the Area Biorefinery Processes & Composite Materials is on optimising the use of biomass – primarily wood – but also other renewable raw materials. With more than 20 years of experience and over 40 highly qualified scientists organised in five research teams, we are a leading research partner for industrial and strategic questions in the fields of wood and wood component chemistry, pulp quality and chemical or biotechnological utilisation of lignocellulosic raw materials.

Our expertise ranges from the pre-treatment of biomass to the digestion in pressurised reactors, the separation of waste and value streams and the development of methods for the required instrumental analysis. Another focus of our research activities is on composite materials made from renewables (NFC – Natural Fiber Composite) as well as bio-based carbon materials. By means of extrusion, injection molding, pressing, melt spinning or 3D-FLM printing, these materials can be processed into innovative products with specifically adjustable property profiles. Our unique know-how also enables us to produce hybrid materials, carbide ceramics and porous carbons from biogenic raw materials and to process them into complex parts. In addition, research is being conducted on the development of bio-based carbon fibers, carbon fiber precursors and in the area of bio-based electrochemistry.

Research topics include:

- Development of fundamental understanding of chemical reactions in digestion processes and translation into new or improved processes

- Pretreatment of biomass to optimise digestion processes

- Efficient cellulose-based specialty products

- Intelligent processes for selective recovery of components in biomass and their further use – as material and/or energetically

- Chemical and/or biotechnological conversion of degradation products of lignocelluloses to platform chemicals

- Downstream chemistry of cellulose, hemicellulose and lignin- derivatisation and functionalisation

- Chemical and/or biotechnological conversion of degradation products of lignocelluloses to platform chemicals

- Downstream chemistry of cellulose, hemicellulose and lignin- derivatisation and functionalisation

- Development of analytical methods - from laboratory to industrial process applications

- Optimisation of thermoplastic processing

- Compounding

- Profile extrusion (also foaming and coextrusion)

- Injection molding (also foaming)

- Melt spinning

- Production of filaments (also short and continuous fiber reinforced) for 3D-FLM printing

- Material development and optimisation of thermoplastic formulations (focus on biopolymers)

- Development of biobased carbide ceramics

- Development of carbon fibers and carbon fiber precursors from biobased raw materials

- Research and development in the field of bio-based components for electrochemical applications (batteries, fuel cells, supercapacitors)

Team Pulp & Fiber Biorefinery

The team Pulp & Fiber Biorefinery is mainly concerned with issues related to chemical pulping of wood, new raw materials for pulp production, and new products made from cellulose fibers. The utilisation of process streams from the pulp and fiber industry is another field of activity in this working group.

Team Chemical Process Technology for Biomass Utilisation

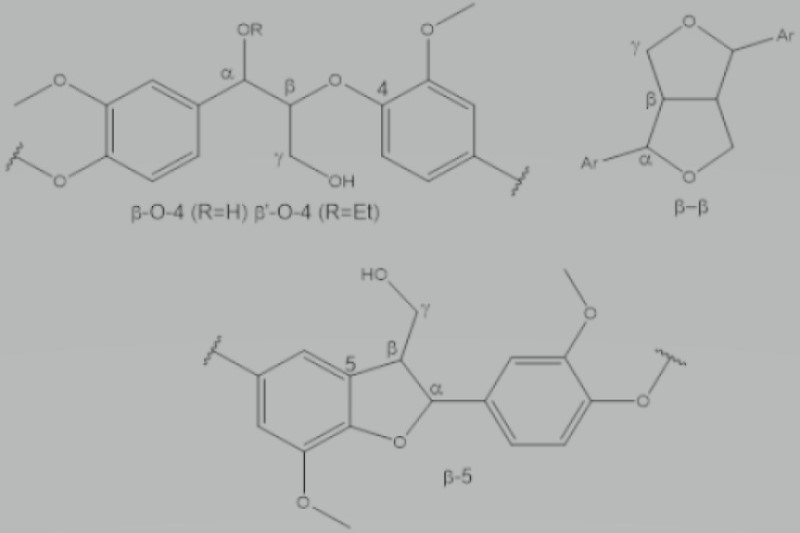

The team Chemical Process Technology for Biomass Utilisation focuses on the modification of cellulosic materials, the generation of green solvents, the material utilisation of lignin and lignin derivatives, in particular heterogeneous-catalytic conversion of degradation products of lignocelluloses to platform chemicals and the development of concepts for a cascading biorefinery.

Team Biotechnological Process Technology for Biomass Utilisation

The team Biotechnological Process Technology for Biomass Utilisation focuses on the biotechnological conversion of process by-products into valuable products and the development of concepts for a cascading biorefinery.

Team Biobased Composites, Applications & Processes

The team Biobased Composites, Applications & Processes focusses on the formulation and process development of innovative biopolymers and composite materials. This includes (natural) fiber reinforced (bio)polymers for plastic processing applications such as injection molding, (co-)extrusion, foaming (injection molding and extrusion), melt spinning, filament production and 3D-FLM printing (short and continuous fiber reinforced polymers). Core areas are ecological considerations, characterisation and selection of raw materials, processability in compounding and molding. Further development of simulation and modeling methods for compounding and plasticising.

Team Biobased Fibers and Carbon Materials

The team Biobased Fibers and Carbon Materials focuses on the development of bio-based carbon materials such as carbon fibers, activated carbon as well as carbon moldings. Core areas are thermal treatment of biobased feedstocks, characterisation and modification of materials, and determination of structure-property relationships. The produced carbon materials are used in composites, filters, electrodes for energy storage, SiC ceramics, etc. Another focus includes research in bio-based materials for electrochemical applications.

Equipment and Methods

In our area, developments, and investigations from laboratory to pilot plant scale can be realised with our own equipment. In addition, cooperations provide access to the equipment of Johannes Kepler University Linz (JKU).

ANALYTICS & MATERIALS TESTING

- Lignin and Carbohydrate characterization

- Pulp analysis I Wet chemical methods

- Pore analysis I Gas adsorption – Hg-porosimeter

- Chromatography I HPLC – SEC – HPAEC-PAD – GC-FID

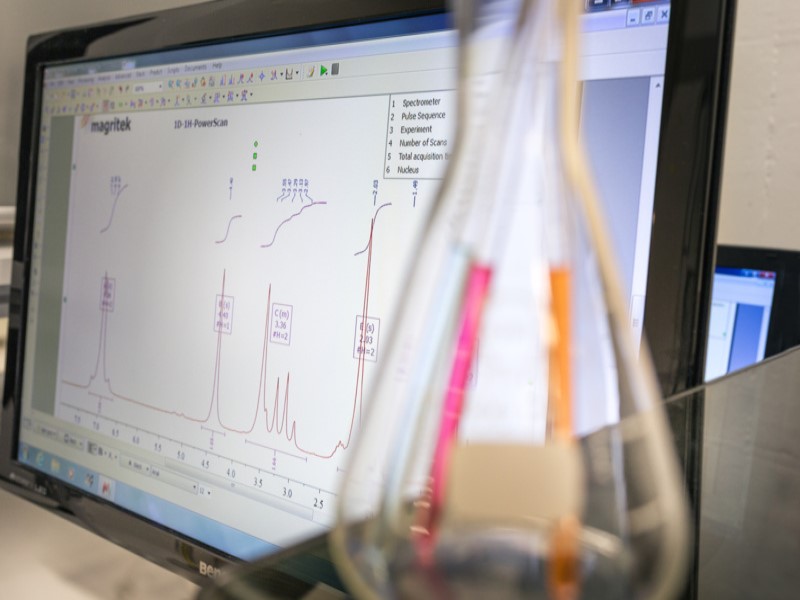

- Spectroscopy I UV-VIS – NMR – React-IR inline – ATR/FTIR heatable – Data analysis

- Thermal analysis I DSC – OIT, High pressure crucibles, Rapid cooling; HDT-A/B/C

- Optical analyses I Microscopy – SEM – XPS

- Mechanical analyses I Tensile, flexural and compression tests – Impact strength – Ball drop test – Component testing – Single fiber/fiber yarn/multifilament tensile test

- Rheology I MFR

- Tensiometry I Contact angle | Surface energy | Surface tension

- Potentiostat I Galvanostat

- Fiber characterization I Sieve tower – Bulk density – Fiber length distribution via FASEP

- (Short-term) Dielectric rigidity I High voltage tester

- Reaction to fire tests I Single-flame source test – UL 94 horizontal and vertical burning test

- Environmental simulation I Accelerated weathering – Xenon weathering chambers – Climate tests

- Heating cooling press 320 × 320 × 200 mm

BIOMASS DIGESTION

- Sample preparation I Ball and cutting mill – Freeze dryer – Extraction

- Pressure reactors I Steel and glass reactor stations 300 ml, 1000 ml, 3000 ml

- Purification and separation I Membrane filtration system laboratory scale – Chromatography column in the laboratory and pilot scale – Ultracentrifuge 8 × 50 ml to 6 x 1000 ml

- Functionalization of biopolymers

BIOTECHNOLOGIAL LABORATORY

- Biotechnological conversion of process streams

- 4-fold parallel fermenter station 2000 ml

- Anaerobic tent

- Standard biotechnology equipment

EXTRUSION/COMPOUNDING

- Pulp extrusion line I Counter-rotating, conical twin-screw extruder – output max. 50 kg/h I Standard downstream equipment

- Various extrusion tools I including slit capillary rheology

- Single-screw extruder – Co-extruder I Output max. 30 kg/h

- Simultaneous, parallel twin-screw extruder I Output max. 15 kg/h

- Counter-rotating, conical twin-screw extruder I Output max. 5 kg/h

- Pelletizing systems I Hot die face pelletizing – Underwater pelletizing – Strand pelletizing

- Filament extrusion line I Short and continuous fiber reinforced 3D printing filaments

- Multifilament melt spinning machine I Output max. 3.0 kg/h

- Measuring kneader I 55 ml – 370 ml

INJECTION MOLDING

- Hydraulic injection molding machine I Clamp force 120 t – Dosing volume 160 cm³ – Injection unit for thermoplastics and thermosets

- Chemical foaming due to exact mold opening

- Various tools I Test specimen geometries – Flow spiral – Plates

- Granule dryer I 4 × 30 – 1 × 50 l

- Toothed roller mill for recycling trials

3D-PRINTING

- FLM 3D printer I Build volume: 390 × 400 × 330 mm

- FLM 3D printer I Multi material kit I Build volume: 250 x 210 x 210 mm

- 3D scanner I measuring fields: 45-500 mm – resolution: 5 megapixels – max. accuracy: 18 μm

HIGH TEMPERATURE PLANTS

- High-temperature chamber furnace I up to 2,300 °C – retort 6 l usable volume

- Chamber furnace I up to 900 °C – 150 l usable volume

- Rotary kiln I up to 1,100 °C

- Tube furnace for oxidation/stabilization I up to 300 °C – 5 heating zones of 50 cm each

- Tube furnace for LT carbonization I up to 1,050°C – 5 heating zones of 50 cm each

- Tube furnace for HT carbonization I up to 1,700°C – 2 heating zones of 50 cm each

Contact Person

in Area Biorefinery Processes & Composite Materials

DI Dr. Robert Putz

Area Manager

Team Leader Chemical Process Technology for Biomass Utilisation

DI Dr. Manfred Schöflinger

Area Manager

Team Leader Biobased Composites, Applications & Processes

DI Dr. Christoph Unterweger

Team Leader Biobased Fibers and Carbon Materials

DI Dr. Michael Egermeier

Team Leader Biotechnological Process Technology for Biomass Utilisation

Profin Dr.in Rer. Nat. Habil

Birgit Kamm

Key Researcher

Contact and Directions

Address

Kompetenzzentrum Holz GmbH

Bereich Biorefinery Processes & Composite Materials

Science Park, Bauteil 2, 2. Stock – Trakt A

Altenberger Straße 69

4040 Linz, Austria

By car via the Highway A1 (Westautobahn)

Leave the A1 at exit Linz and take the A7 (Mühlkreisautobahn) in the direction of Linz; Exit: Linz-Dornach; straight ahead until the Johannes Kepler University Linz; the Science Park is at the right side (parking garage available).

By train

Go by train to “Hauptbahnhof Linz” and take the tramway 1 or 2 (direction “Universität”) to terminal stop “Universität”; then 5 minutes by foot to the Science Park.