Smart composite &

surfaces

Research Interests

At St. Veit/Glan our research is focused on the topic surface technology concerning wood based products and bio based composites.

In synergy with our industrial and scientific partners the work is carried out by our well educated researchers to establish a high expertise. This allows for long term cooperation with big firms and enables the first research steps for small size enterprises. Our offers range from foundational research up to generation of prototyping.

Research topics include:

- Investigation of (production) processes for their more efficient design

- Characterisation of surfaces

- Development of methods for surface characterisation

- Atmospheric pressure plasma treatment for surface modification/activation and coating

- Surface modification/activation and coating

- Use of statistical test planning and AI-supported modeling for knowledge-based material development

- Development and optimisation of powder coating technologies for wood-based materials, natural fiber composites and paper

- Functionalisation of surfaces by integrating new technologies such as printed electronics, self-healing or self-cleaning properties

- Development of flexible, sensor-integrated laminate layers for functional applications

- Process optimisation to specifically influence the surfaces of papers, in particular decorative, sack and kraft papers

- Data-driven material development through sensor-based data acquisition and spectroscopic analysis methods

- Interdisciplinary research into the development of intelligent, sustainable materials with innovative functionalities

- Research of bio-based fiber composites with a focus on sustainable matrix and reinforcement materials for the circular economy

- Expansion of the property profile of laminates in terms of look, feel, scratch resistance and structural design

To offer the best possible support to our clients the research issues have been put into execution by five teams:

Team Coating Technologies

The research focus deals with the powder coating technology of wood based panels, natural fiber composites and composite materials for furniture and interior applications as well as their functionalisation (integration of printed electronics, self-healing,…). Another core area is the surface modification and functionalisation using plasma activation and coating under atmospheric pressure conditions.

Team Green Long Fiber Materials

The team Green Long Fiber Materials investigates and develops high-performance materials made from wood fibers and natural fibers for lightweight applications in the automotive and non-automotive sector as well. In particular we would like to point out the development of long fiber reinforced thermoplastics based on flax fabrics for automotive seat shells and bio-based composites made from biopolymers and flax fabrics for furniture (e.g. chairs), sports equipment (e.g. skateboards) and structural components (e.g. rotor blades of small wind turbines). One of the principal research objectives comprises the synthesis of biopolymers from renewable resources for the purpose of using them as bio-based matrix component of plant fiber reinforced composites (green composites) or as binder of bio-based coating materials.

Team Laminates

The aim of this work group is to enhance the properties of laminates. This ranges from surface functionalisation (appearance, haptic, scratch resistance, printability, self-healing, self-cleaning,…) to functionalisation of the layer composites (deformation properties, integration of sensors and interlayers,…).

Team Paper Properties

This team has its focus on the optimisation of paper properties. This covers issues which analyse the impact of different process parameters and process steps on the surface properties of different kind of papers (décor paper, kraft paper, sack paper).

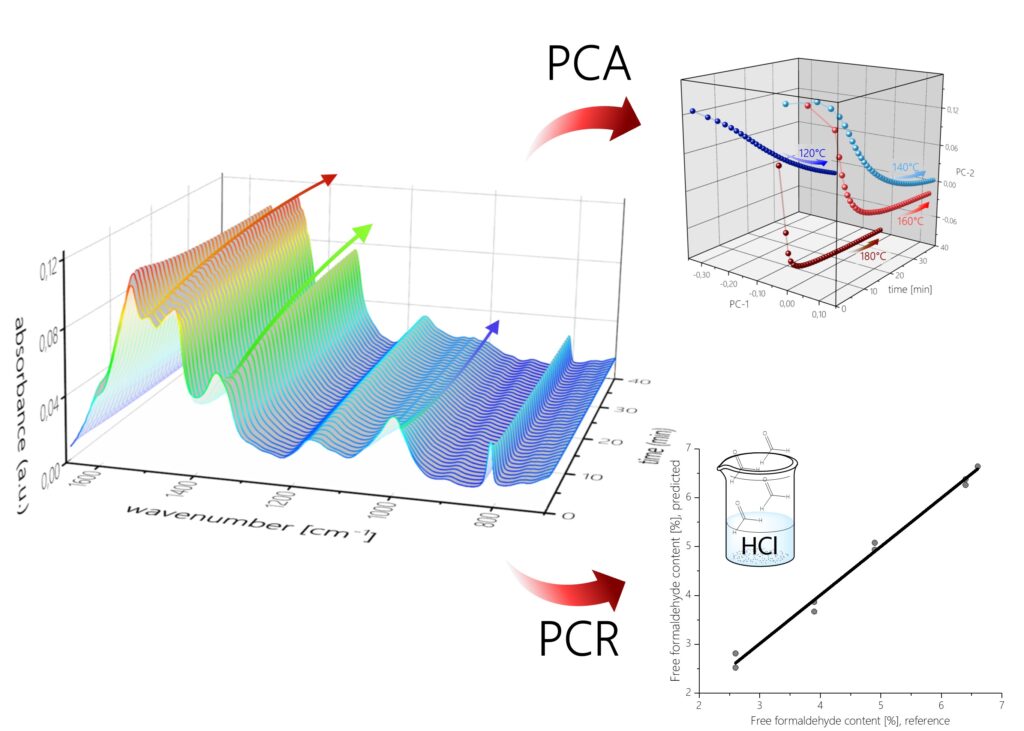

Team Data Based Material Development

The data-based material development team employs advanced approaches and technologies to design, analyse and optimise materials and processes across diverse applications. Sensors from renewable materials and spectroscopic data, coupled with statistical design of experiments, form the foundation for data collection to support the development of knowledge-based models. By harnessing the capabilities of data analytics and promoting collaboration across various disciplines, we drive innovation to craft materials with smart and intelligent properties, enhanced functionality and a heightened level of sustainability.

Equipment and Methods

In the field of Smart Composites & Surfaces at our site in St. Veit an der Glan, we have excellent analytical methods specialized in the characterization of surfaces. This offer is rounded off by comprehensive laboratory and pilot plant equipment, as well as wet-chemical and climatic laboratory facilities. In addition, through the cooperation in our scientific and industrial network, there is access to further state-of-the-art infrastructure.

MATERIAL CHARACTERISATION

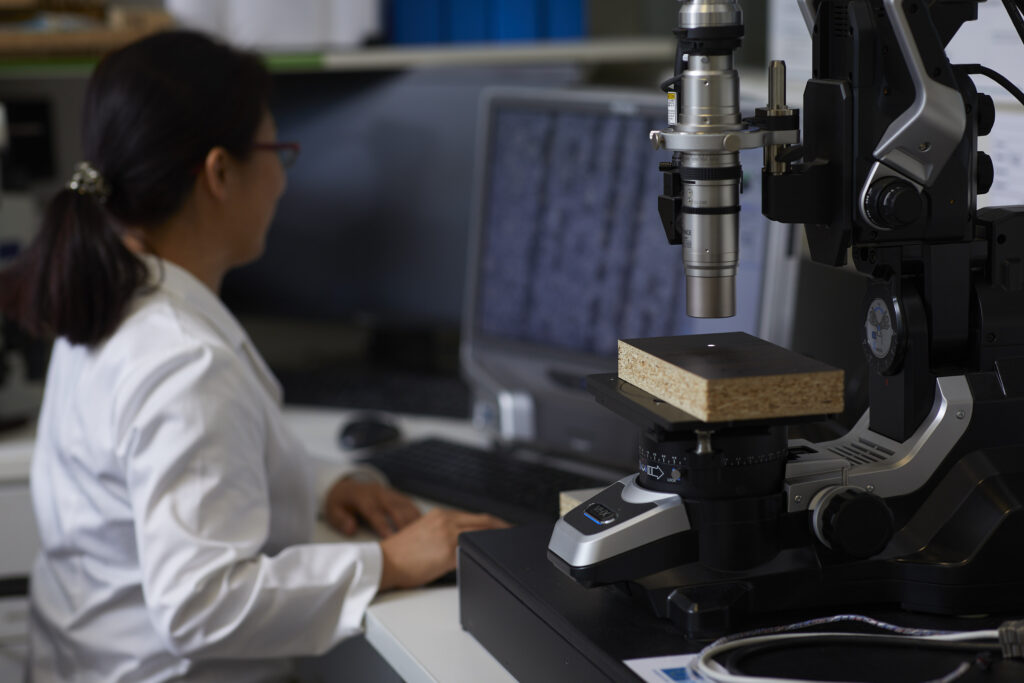

MICROSCOPIC METHODS

- Microscopic Analyses I AFM – Fluorescence Microscopy – Reflected Light and Transmitted Light Microscopy – Digital Microscopy – Laser Scanning Microscopy

- Image Analysis | 3D Surface Measurement – Surface Roughness, Waviness, Primary Profiles

- Preparation techniques I Rotational and ultra-microtome – Dyeing techniques – Grinding and polishing techniques

SPECTROSCOPIC METHODS

- MIR area I ATR/FTIR heat able– locally resolved – ad line – inline

- NIR area I Diffuse Transmission – Diffuse Reflection – Directional Reflection – Hyperspectral Imaging

- UVVIS area | Diffuse Transmission – Diffuse Reflection – Directional Reflection

- Multivariate Spectra Analysis

THERMAL ANALYSES

- DSC I specific heat capacity – crosslinking kinetics MFK

- TGA with FTIR coupling I Mass degradation incl. identification of gases – content, moisture or solvent – Determination of thermal stability – Oxidation stability – Decomposition kinetics

- TMA I thermal dimensional change – coefficient of expansion – swelling behaviour – glass transition temperature

PHYSICAL AND MECHANICAL ANALYSES

- Mechanical analyses I Tension – Compression

- Environmental simulation I fast weathering – outdoor weathering – climate testing

- Rheologie

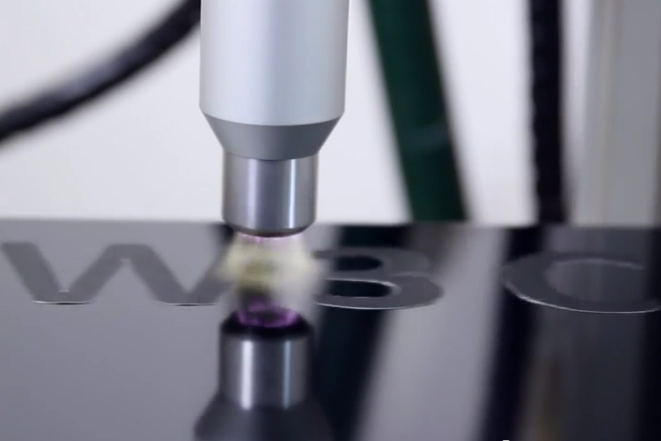

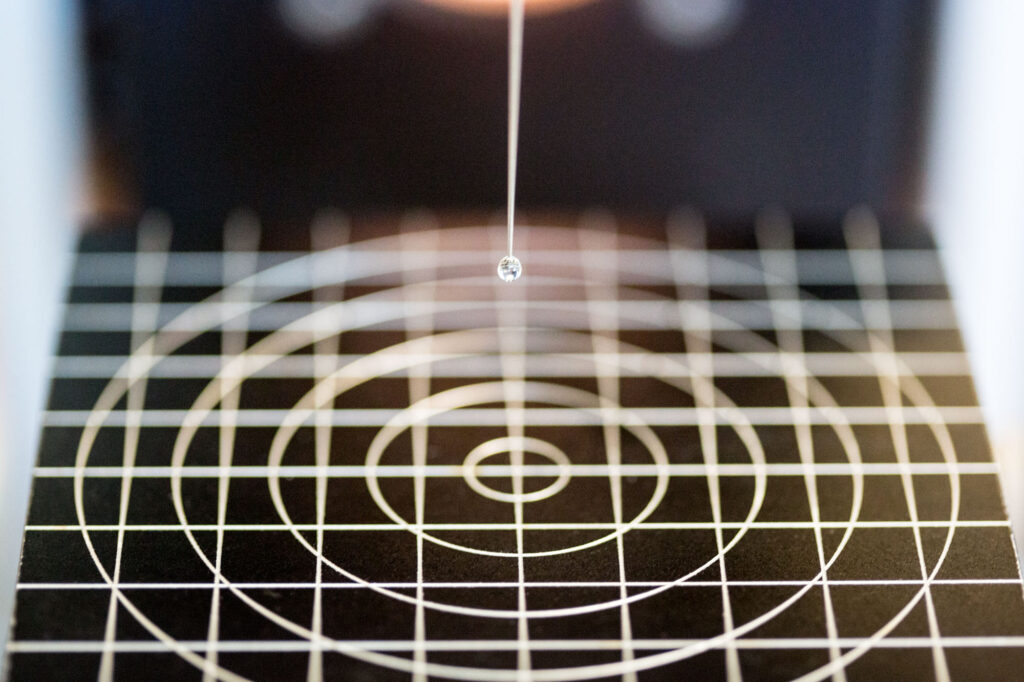

- Tensiometry I Contact angle | Surface energy | Surface tension

- Electroacoustic spectrometer for particle size analysis

- Dielectric Analyses I Curing Kinetics

- Surface testing of wood-based materials

- Paper Exams | Formation Analysis – Penetration Behavior – Smoothness – Gurley

- Moisture measurement I Water content measurement I Steam sorption measurement

- Thermography | active and passive – monitoring and control of process temperatures – steady-state microthermography

- Measurement data acquisition systems

DIGITAL TECHNOLOGIES & METHODS

- Multivariate data analysis I Prime Component Analysis – Prime Component Regression – PLS Regression – Multiple Linear Regression – Cluster Analysis – Multivariate Curve Resolution

- Multivariate Statistical Modelling I Finite Element Modelling

- Statistical design of experiments I Design Experts

PILOT AND PILOT PLANTS

COMPOSIT TECHNICUM

- Up Scaling Batch Reactor 5 L

- Laboratory foulard I Impregnation or dyeing of nonwovens, mats, textiles

- Spray drying of polymer dispersions

- LCM process

- FEM Analyse Software I Pre- Post Processing – Simulation of fiber composite components

- Deformation analysis with Auto Grid I optical

3D-PRINTING

- Desktop Continuous Fiber Printer | Glass – Aramid – Carbon in Polyamide Matrix

COATING TECHNOLOGIES

- Heating Cooling Press 760 × 420 mm | Mould carrier press 600 × 600 mm

- Atmospheric Pressure Plasma | Activation and coating

- Powder coating | electrostatic infrared curing of natural fibre composites

- MDF, natural fiber composites, metal, chipboard, WPC

- UV polymerization of UV curing systems

- Film applicators | Automated and manual

Contact Person

in Area Smart Composites & Surfaces

DIin Dr.in Edith Zikulnig-Rusch

Area Manager

Team Leader Laminates, CSR Management

DIin Dr.in Olivia Moser

Deputy Area Manager

Team Leader Analytics & Methods

Priv.-Doz. DI Dr. Arunjunai

Raj Mahendran

Team Leader Data Based Material Development

DI Dr. Günter Wuzella

Team Leader Green Long Fiber Materials

Contact and Directions

Address

Kompetenzzentrum Holz GmbH

Area Smart Composites & Surfaces

Klagenfurter Straße 87-89

9300 St. Veit an der Glan, Austria

By car from Salzburg, Villach

Via “Tauernautobahn” (A10) – direction Klagenfurt/Graz (A2) – exit Klagenfurt Nord – take the B 83 direction St.Veit/Glan – after about 20 km exit Glandorf/St. Donat – turn left – after about 0.5 km W3C St. Veit on the left side.

By car from Graz

Via “Südautobahn” (A2) – direction Klagenfurt – exit Klagenfurt Nord – take the B 83 direction St.Veit/Glan – after about 20 km exit Glandorf/St. Donat – turn left – after about 0.5 km W3C St. Veit/Glan on the left side.

By car from Vienna

Via A2 – at exit Seebenstein – direction Bruck an der Mur (S6) – at interchange Sankt Michael (133) move to S36 – direction Italy, Klagenfurt – exit Judenburg West – direction Scheifling/Klagenfurt (B 317) – exit Glandorf – turn right – after about 0.5 km W3C St. Veit/Glan on the left side.

Public transport

From bus or train stop “St. Veit/Glan” or “Glandorf” ~ 3 minutes walk.