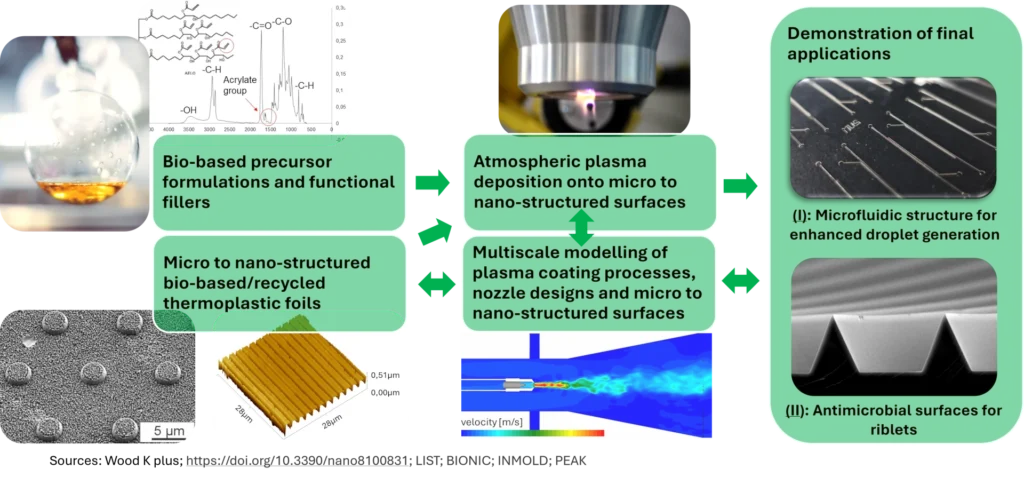

The aim of the InnoCoat4Plasma project is to develop bio-based coatings with functional fillers that are applied using atmospheric pressure plasma technologies and improve the technological and antimicrobial properties of imprinted thermoplastic foils for microfluidic and riblet applications. The solutions are evaluated and optimised using multiscale modelling.

Project goals & contents:

Fluid dynamic surfaces and coatings are in high demand in various industries such as food, cosmetics and paper production. While flow optimisation is achieved by bio-mimicking structured surfaces, durable antimicrobial and hydrophilic/hydrophobic properties can only be achieved through additional coatings. This poses the challenge of addressing the sophisticated functionality of the surface appropriate to the end-use while reducing raw material use and saving energy for its application. The substitution of fossil resources, energy-efficient use and recyclability of the end products are also goals of sustainable development, the circular economy, and the European Green Deal.

InnoCoat4Plasma is based on the concept of combining bio-based coatings, recycled thermoplastic foils with imprinted micro- to nanostructures and an environmentally friendly application process with low chemical by-products and less energy consumption. Bio-based pre-polymers (e.g. from vegetable oils) and fillers from plant extracts are used to develop non-hasardous coatings. An innovative target is the plasma functionalisation of particulate fillers to improve their dispersibility and compatibility to the matrix polymer. Research is being intensified by multiscale modelling of plasma processes (plasma-surface interaction, thin film formation), new nozzle designs for selective microstructuring using plasma techniques and simulation of structured surfaces in contact with various liquid media. To evaluate the potential of the developed coatings for industrial use, application trials using atmospheric pressure plasma and characterisations of the coatings are being carried out, supplemented by the production of two demonstrators.

Lead partner:

Wood K plus - Kompetenzzentrum Holz GmbH

Project lead:

DI.in Judith Sinic

Project partners:

Luxembourg Institute of Science and Technology (LUX), Inmold A/S (DNK), bionic surface technologies GmbH (AUT), Peak Emulsions ApS (DNK)

Research programme / Project ID:

Advanced Materials, M-ERA.NET Call 2024, National: FFG-KLWPT/FFG-No.: FO999924622

Project periode:

April 2025 - March 2028

Project budget:

EUR 1,345,893

Funding:

The project is funded by the Austrian Research Promotion Agency (FFG) with funds from the Federal Ministry for Innovation, Mobility and Infrastructure, the Luxembourg National Research Fund (FNR) INTER/MERA24/19101873/InnoCoat4Plasma and the Innovation Fund Denmark (IFD) H2-M-ERA.NET 3-Call 2024/project12199/InnoCoat4Plasma as part of the Advanced Materials, M-ERA.NET Call 2024 (Project ID: 12199).