Hybrid NFC with Excellent Impact Strength

Together with Borealis Polyolefine and Budapest University of Technology, notched impact strength of polypropylene (PP) based Natural Fiber Composites (NFC) has been highly increased by the development of innovative hybrid materials. We used special polymeric fibers as impact modifiers for NFC. In the present development, PP impregnated long fibers were applied for the first time as impact modifier for NFC. Longer fibers are more effective reinforcements in thermoplastics than shorter fibers. Materials with high impact strength, which show improved crash performance, are of importance in the automotive industry.

Highly Improved WPC Formulation

NFC (Natural Fiber Composites) are composite materials based on a polymer matrix and wood or natural fibers as filler, supporting a natural design. Besides, for example in a polypropylene (PP) matrix, wood or natural fibers can significantly reinforce the stiffness of the thermoplastic matrix material in injection molded parts. To further improve the impact strength of such a material, which is necessary to improve crash performance, it is either possible to improve the matrix by using directly a heterophasic PP copolymer or by using externally added elastomers. Nevertheless, both concepts lead to a significant reduction of other important properties such as tensile strength and stiffness.

In this research work package polymer fibers as impact modifier for wood filled composites are used. From our own previous successful studies, it was known that short polyvinyl alcohol (PVA) fibers as filler improve the impact behavior of PP dramatically and that the tensile properties have been improved simultaneously; besides, we developed together with the Budapest University of Technology that special short polyethylene terephthalate (PET) fibers improve the property profile of NFC better than elastomers. In both cases, impact strength was improved due to the pull-out process of the fibers during testing.

In the present research study for the first time PP impregnated long polymer fibers as impact modifier for NFC are used. Longer fibers are a more effective reinforcement in thermoplastics than shorter fibers. The applied 15 mm fiber pellets were specifically developed, produced and provided by our industrial project partner Borealis Polyolefine GmbH.

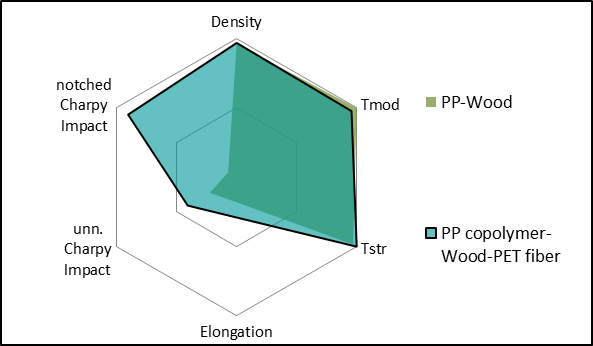

Injection molded PP – wood – PET fiber formulations showed a synergistic effect by using both fillers in PP. Addition of wood flour results in an increase of tensile properties and the addition of PET fibers in an increase of notched impact strength compared to the PP matrix. The hybrid combination acts as impact modifier for NFC. Processing temperature and initial fiber length were decisive factors to achieve a good performance of the molded specimens. Tensile properties were kept constant.

Lightweight materials with sufficient notched impact strength exhibit a good crash performance and can be used in the automotive industry.

Impact and effects

This innovative wood based hybrid material presents a composite with outstanding impact and stiffness performance in combination with a natural product design. Regarding this research topic, patent applications have been filed (e.g. EP3263641A1).

Among other applications, such natural fiber polymer composites can be used in injection molding. Injection molding is the worldwide most important processing method for plastics.

The advantages of the use of cellulosic and natural fillers are their outstanding weight specific reinforcing effects to obtain lightweight materials and their very low environmental impact during their production. Moreover, there are also benefits in the product design.